Cummins PowerCommand® X-Series Transfer Switch series rely on proven Cummins technology to deliver fail-safe performance in mission critical applications. But they’re just one component of a completely integrated power system that encompasses decades of application expertise, comprehensive system engineering, exhaustive testing and validation, and a global network of advanced electrical engineers capable of providing on-site service and support.

PRODUCT Detail

The PowerCommand® X-Series consists of 40-3000A automatic and non-automatic transfer switches with non-service and service entrances. Each product in this suite features the state-of-the-art PowerCommand® 80 control and are designed for markets and applications where the highest performance and system connectivity are required.

Designed for operation and switching of electrical loads between primary and alternate power sources, the X-Series switches can be used in utility-generator set, utility-utility, generator set-generator set, or three source system (dual standby) applications and are suitable for use in emergency, legally required, and optional standby applications.

In addition, the X-Series offers a full range of industry leading UL1008 Time Duration WCR and Short-time based rating, achieved by Cummins High Endurance Mechanism with patented Blow-on technology, delivering the next level of performance and reliability.

In addition, the X-Series offers a full range of industry leading UL1008 Time Duration WCR and Short-time based rating, achieved by Cummins High Endurance Mechanism with patented Blow-on technology, delivering the next level of performance and reliability.

Designed by Cummins experts, the revolutionary PowerCommand® 80 control is a single integrated control All functionalities can easily be implemented as needed without add-on hardware nor extra modules needed.

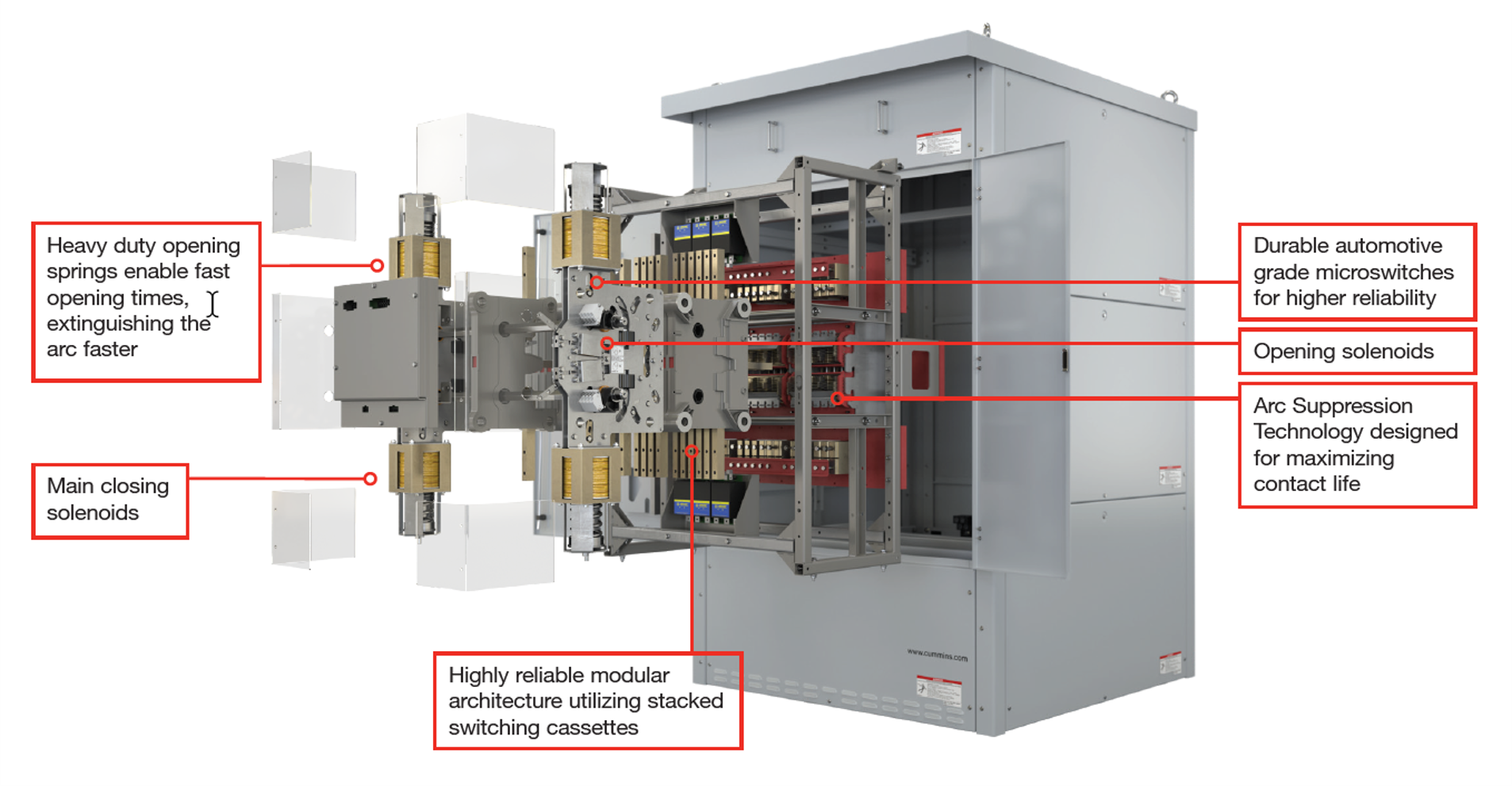

Innovative design of the High Endurance Mechanism and Blow-on Technology

The High Endurance Mechanism (HEM) is designed to minimize the contact damage during a fault condition, thus retaining its capacity to carry up to 100% of its rated load. Electromagnetic forces developed during a fault cause a conventional transfer switch’s contacts to blow open, producing destructive arcing that often results in extensive internal damage to the switch.

Typically, after a conventional switch experiences a fault, its contacts, arc chutes and in some cases, its control will need replacing. However, the blow-on Technologies utilized by the HEM uses the same electromagnetic energy to hold the contacts closed during a fault, practically eliminating arcing, contact damage, and performance degradation. When a fault occurs, electromagnetic fields develop around moving and stationary contact arms. The HEM utilizes the resulting electromagnetic forces to firmly hold the contacts together. The higher the fault current the greater the force. With the high short-time ratings of this innovative blow-on technology, costly repairs or inconvenient downtime can be minimized after a fault.

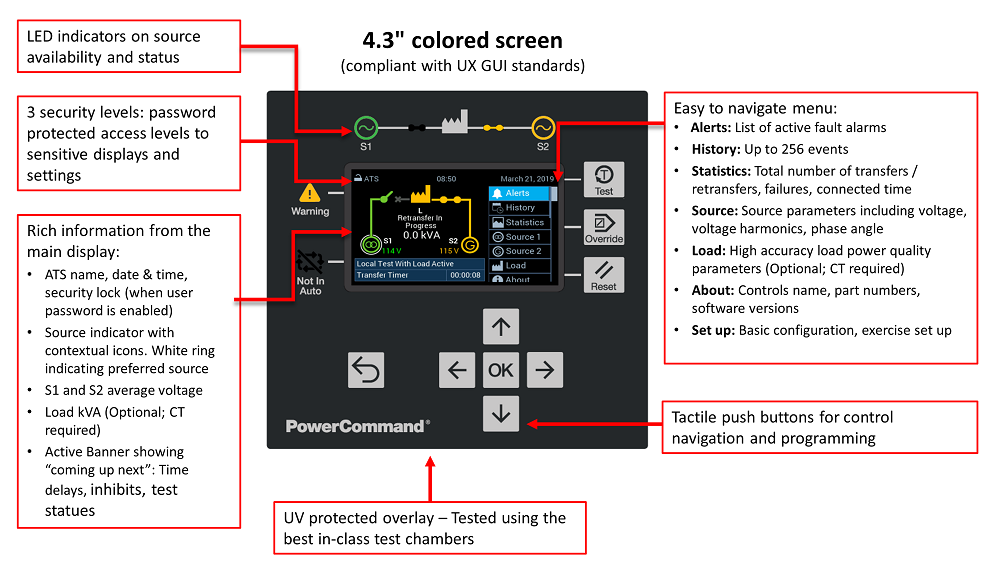

PowerCommand® 80 Transfer Switch Control

The revolutionary PowerCommand® 80 Transfer Switch Control delivers unrivaled adaptability, connectivity and intelligence. Designed by Cummins Power Generation experts, the PowerCommand® 80 is a single integrated control – no extra modules are need. All functionalities can easily be implemented as needed without add-on hardware. In addition, the control features a highly customizable customer inputs/outputs which can be tailored to suit a wide range of application requirements.

Easy to navigate HMI

The control human machine interface (HMI) includes a LED backlit LCD display with tactile-feel soft-switches for easy operation and screen navigation. All data on the control can be viewed by scrolling through screens with the navigation keys. Forward and backward navigation functionality is also provided. The control displays the current active fault, fault occurrences and time-ordered history of the 256 previous faults with respect to Real Time Clock Stamp and Engine Running Time.

Stay in touch with critical data with the PowerCommand Transfer Switch Remote Annunciator

The PowerCommand Transfer Switch Remote Annunciator allows you to remotely monitor up to eight X-Series transfer switches on one easy-to-read color LCD screen.

The PowerCommand Transfer Switch Remote Annunciator allows you to remotely monitor up to eight X-Series transfer switches on one easy-to-read color LCD screen.

At a glance, you will know the transfer switch position, source availability, and whether there are active events or alerts.

An intuitive user interface provides you access to additional information for each transfer switch, including source voltage, frequency, and alert logs and command functions to initiate tests, override transfer timers, and load shed remotely.

- Market-leading intuitive design

- Color-coded symbols and icons

- Tactile feedback buttons

- Remote monitoring

- Detailed information and history

- Remote test, override and shed control

- Fault and event notification

- Voltage and frequency metering

- Hardwire support for one non-X-Series controller

Wherever you are, whatever your job, Cummins expertise is Always On

Cummins offers customers unrivaled peace of mind when it comes to servicing and maintaining digital master controls. Best-in-class aftermarket capabilities via your dedicated local contact, supported by a global system of service technicians, engineers, 8,00 dealer locations and 500 part distribution facilities in over 190 countries spread across 6 continents.

Application features:

- 40A – 3000A, 600V and below

- Withstand and closing ratings

- Time Based 0.05s (3 cycles), Short-time 0.5s (30 cycles)

- Service and non-service entrance

- Applications:

- Utility-Gen, Gen-Gen, Utility-Utility, Dual Standby

- Transfer Modes:

- Open, closed, non-automatic

Key PowerCommand® 80 control features:

- Standard features:

- Integrated Modbus communication (RS485 and TCP/IP)

- Standard Customer I/O

- Advanced Power Quality Metering

- Automatic Load Management

- Source inversion

- Optional features:

- Integral Control Power supply

- Premium customer I/O

- Load shed

- Integral redundant control power supply options

Product certifications:

- UL1008/CSA22.2 No. 178.1

- UL/NFPA20 (fire pump)

- International Building Code (IBC) seismic

- OSHPD Seismic Pre-Approval certificate

Other configurable options:

- Integral redundant control power supply options

- Motor disconnect switch

- Surge protection device

- Utility grade power meter (PM8000)

- Secured front cabinet

- Anti-condensation heaters

- Lug options:

- No lugs (bus stabs)

- Mechanical lugs

- Compression lugs

ดาวน์โหลดโบร์ชัวร์สินค้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ

similar products

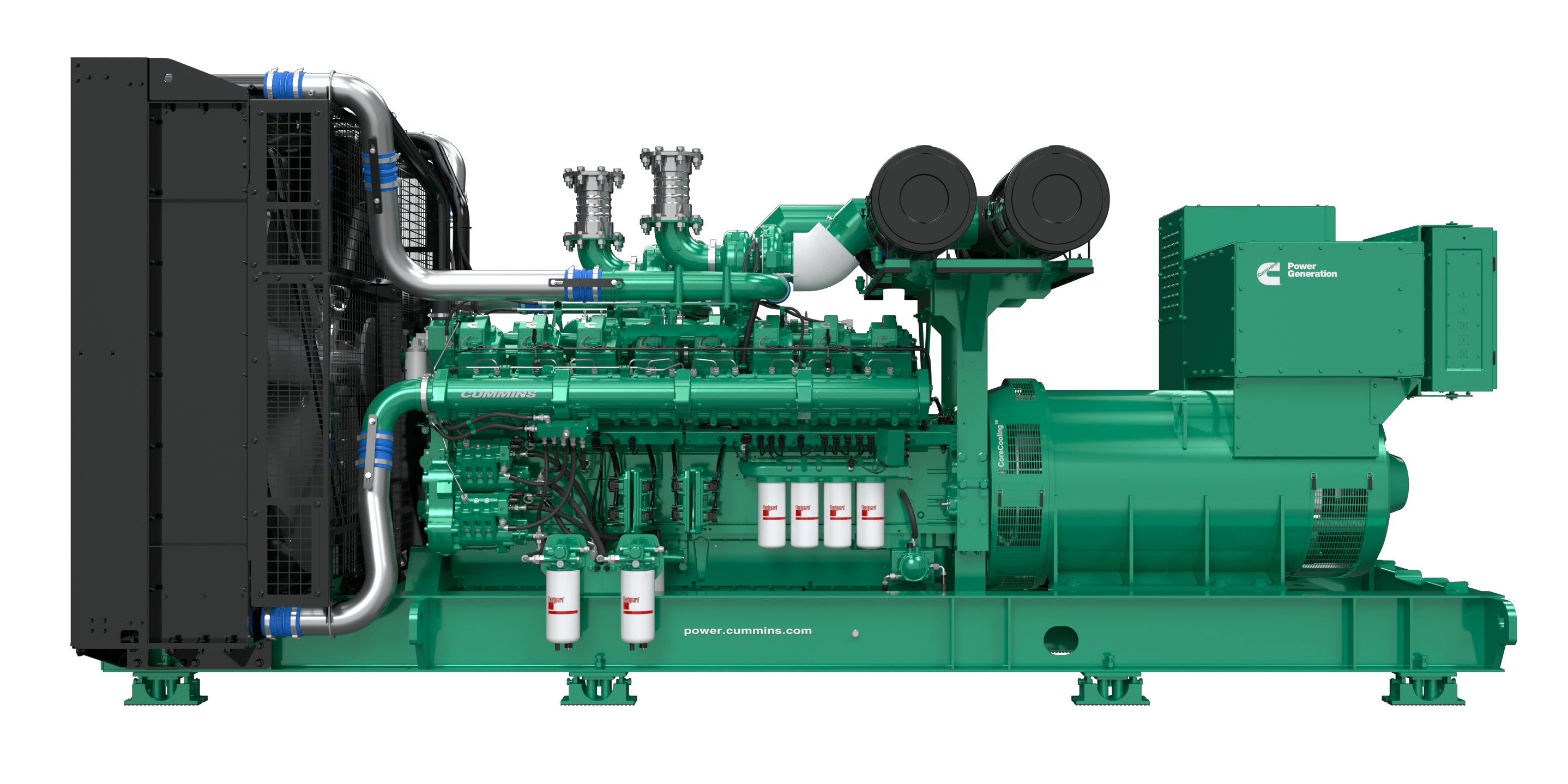

C1750D6E / C2000D6E Centum Series

Amps

-

Voltage

60 - 60

Certification

EPA Tier 2

C1750D6E / C2000D6E Centum Series

Amps

-

Voltage

60 - 60

Certification

EPA Tier 2

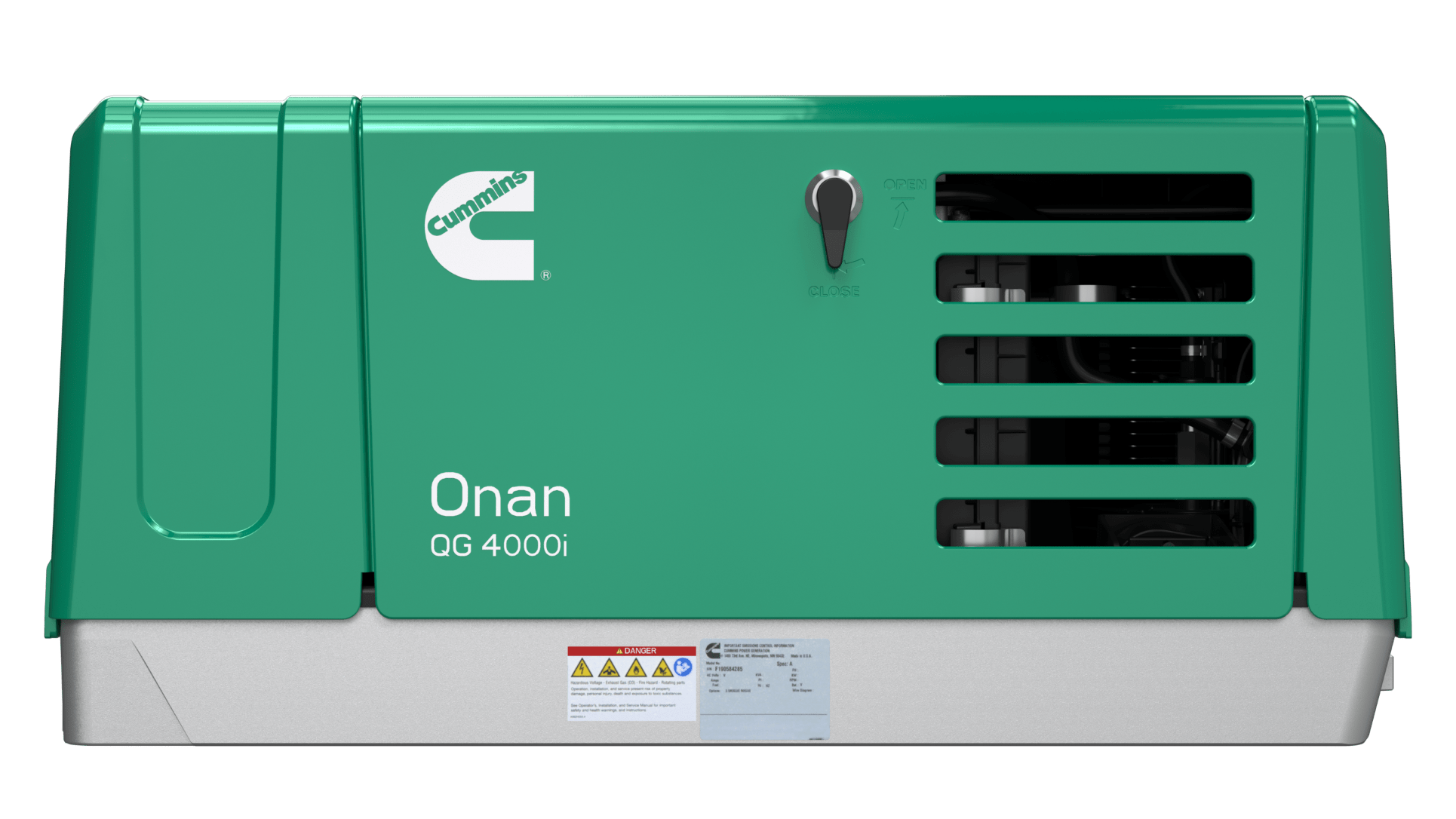

QSB5-G13, QSB5-G6

Amps

-

Voltage

-

Certification

EPA Tier 3

QSB5-G13, QSB5-G6

Amps

-

Voltage

-

Certification

EPA Tier 3

QSB5-G13, QSB5-G6

Amps

-

Voltage

-

Certification

EPA Tier 3

QSB5-G13, QSB5-G6

Amps

-

Voltage

-

Certification

EPA Tier 3

QSB5-G13, QSB5-G6

Amps

-

Voltage

-

Certification

EPA Tier 3

QSB5-G11 for Rental

Amps

-

Voltage

-

Certification

EPA Tier 4F, EU Stage IIIA

QSB5-G11 for Rental

Amps

-

Voltage

-

Certification

EPA Tier 4F, EU Stage IIIA

QSB5-G11 for Rental

Amps

-

Voltage

-

Certification

EPA Tier 4F, EU Stage IIIA

QSB5-G11 for Rental

Amps

-

Voltage

-

Certification

EPA Tier 4F, EU Stage IIIA

QSK78 for Data Center Continuous (DCC) Rating

Amps

-

Voltage

-

Certification

N/A, EPA

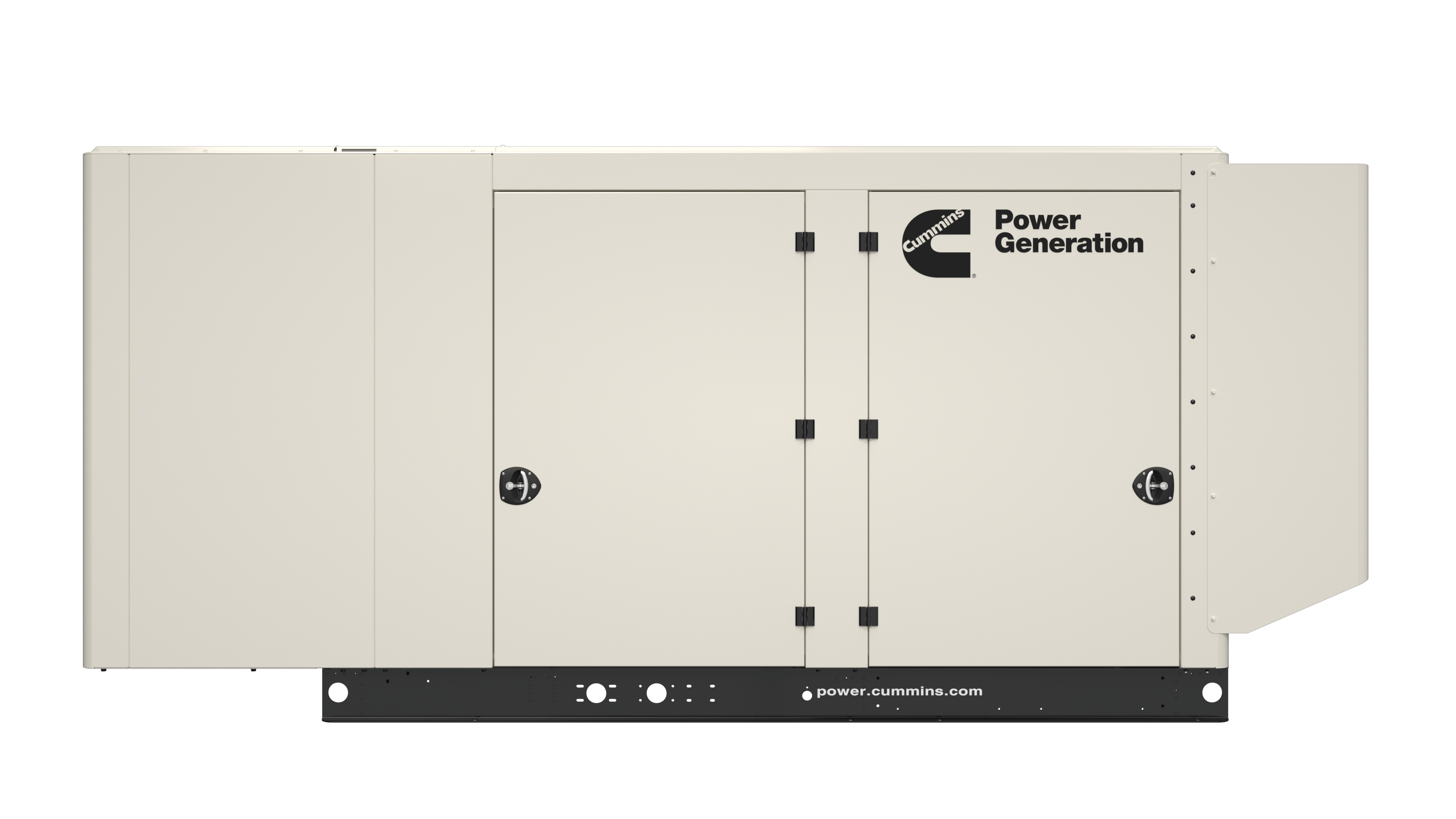

KTAA19 for Commercial Industrial

Amps

-

Voltage

-

Certification

N/A

KTAA19 for Commercial Industrial

Amps

-

Voltage

-

Certification

N/A