PRODUCT Detail

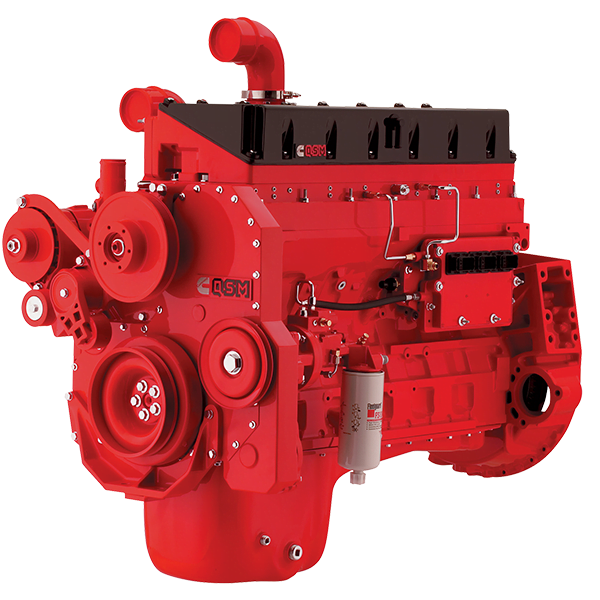

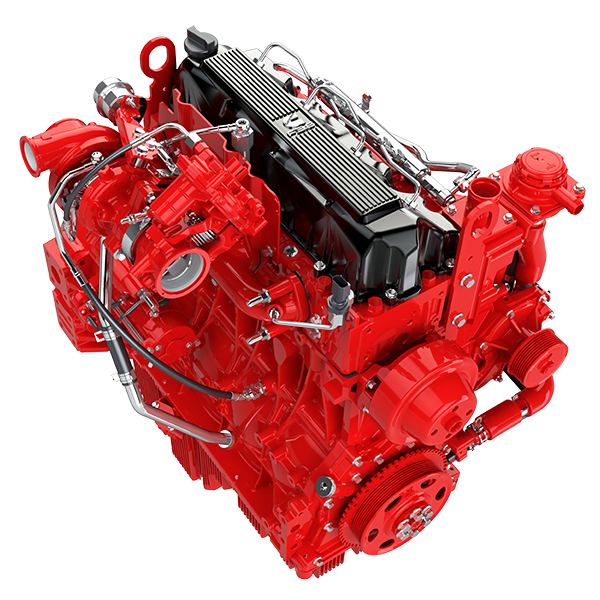

Wellhead compression applications require reliability and durability not found in every natural gas engine. For dependable operations and world class support, you need the Cummins GTA8.3SLB – an emission compliant, high-performance natural gas engine that shares the proven heritage of the Cummins C Series diesel engines and many of the same heavy-duty components. You can depend on the GTA8.3SLB to stay emissions compliant, keep maintenance costs down and the gas flowing. Every day.

General Specifications

Inline 6-Cylinder, 4-Cycle, Natural Gas

| Bore | 4.49 in (114 mm) |

| Stroke | 5.32 in (135 mm) |

| Displacement | 8.3 L (505 cubic in) |

| Engine Power* | 175 hp (130 kW) |

| Compression ratio | 8.5:1 |

| Aspiration | Turbocharged and aftercooled |

| Exhaust Type | Dry manifold |

| Weight** | 1650 lb (748 kg) |

| Lube oil capacity | 8.5 gal (32.0 L) |

| Rotation | Counterclockwise |

* Rating dependent

** Weight is approximate and varies with options.

Engine Technical Data

| Model | GTA8.3SLB | |

| Curve Number | FR-93002 (2) | |

| Exhaust Type | Dry | |

| Output Power (1) 100% 75% | HP (kW) HP (kW) | 175 (130) 131 (98) |

| Engine Speed 100% Max Turn Down | RPM RPM | 1800 1350 |

| Aftercooler Water Temperature | °F (°C) | 130 (54.4) |

| Compression Ratio | 8.5:1 | |

| Emissions Data – Engine-Out Emissions (1) NOx CO NMHC THC | g/hp-hr (g-kW-hr) g/hp-hr (g-kW-hr) g/hp-hr g/hp-hr |

|

| Fuel Consumption (1) 100% 75% | BTU/hp-hr (MJ/kW-hr) BTU/hp-hr (MJ/kW-hr) | 8150 (12) 8600 (12) |

| Heat Rejection (1) Jacket Water Aftercooler Exhaust | BTU/min (kW) BTU/min (kW) BTU/min (kW) | 4700 (83) 1346 (24) 8118 (143) |

| Exhaust System (1) Flow Rate Stack Temp Max Back Pres. | ft3/min (L/s) °F (°C) in-Hg | 947 (447) 1359 (737) 2 |

| Intake System (1) Flow Rate Max Restriction | ft3/min (L/s) in-H2O | 443 (209) 15 |

| Gas Pressure | Min – Max in-H2O | 7-25 |

General Dimensions

| Dimensions* | NA | |

| Length | Inches (mm) | 59.7 (1516) |

| Width | Inches (mm) | 34.4 (875) |

| Height | Inches (mm) | 52.1 (1324) |

* Dimensions are approximate and vary with options.

Disclaimers

(1) All data is based on the engine operating with fuel system, water pump, and 8 in H2O (1.99 kPa) inlet air restriction with 4 in (102 mm) inner diameter, and with 1 in Hg (3 kPa) exhaust restriction with 4 in (102 mm) inner diameter; not included are alternator, fan, optional equipment and driven components. Coolant flows and heat rejection data based on coolants as 50% ethylene glycol/50% water. All data is subject to change without notice.

Designed for the oil and gas market, the GTA8.3SLB delivers exceptional dependability and low cost of operation.

Base Engine – Most major components, including block, crank, cam, gears and liners are common with the proven C series diesel.

Emissions – Lean burn combustion EPA certified to the 2008 SI NSPS emissions. Site validation test is not required.

Air/Fuel Ratio Control – Oxygen sensor-based air/fuel ratio control maintains emissions rate and fuel consumption. Display shows O2, control valve position and fault codes and provides for user input.

Air Handling – Turbocharged and aftercooled design delivers reliable performance and life.

Fuel System – Impco carburetor provides stable operation and fuel tracking through all load ranges.

Speed Control – ECM based speed control and an integral throttle body and actuator provides precise and stable rpm control under all load conditions.

Ignition System – Cummins Programmable Control Ignition Module provides precision control by cylinder and optimal spark-voltage output for superior combustion control.

Lubrication System – High-capacity oil pan and combination full-flow and bypass oil filter reduce maintenance costs and extend service intervals.

Commonality – All electronic Cummins gas compression engines utilize common AFR control components and strategy to minimize parts and maximize technician effectiveness.

Warranty – Cummins one year, unlimited hours. Backed by a worldwide distributor network.

Standard Equipment

Air Inlet System

- Factory installed heavy duty air cleaner

Cooling System

- Two pump / two loop cooling system

- Gear driven jacket water pump

- Gear driven auxiliary coolant pump

- Coolant filter for added corrosion protection

- Thermostat controlled jacket water circuit

Exhaust System

- Tuned dry manifold for optimal exhaust flow

Fuel System

- Impco carburetor

- Fisher S-302 regulator

- Cummins proprietary air fuel ratio control with optimized control algorithm

- Full authority Air Fuel Ratio (AFR) fuel control valve

Speed Control System

- Woodward 1724 electronic governor

Digital Display

- AFR system status

- Engine fault codes with history

- Warning and shutdown information

- User interface eliminates need for a laptop for engine adjustment or commissioning

Lube Oil System

- Crankcase breather

- High capacity oil pan for extended oil drain intervals

- Combination full flow and bypass oil filter

Safety Shutoff Protection

- Intake manifold temperature

- Low oil pressure

- Overspeed

Mounting Arrangement

- Four point mounting

- Lift provisions on engine

Flywheels and Flywheel Housings

- Flywheel SAE #3

- Flywheel housing – SAE #3 Cast-iron, machined to accommodate starter mounting

- SAE #2 and SAE #1 FW/FH options available

Electrical System

- 24-volt alternator

Starting System

- 24-volt starter

Power Take-Off

- Front crankshaft pulley

- Front stub shaft optional

ดาวน์โหลดโบร์ชัวร์สินค้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ

similar products

QSB5-G11 for Rental

Power

-

Torque

-

Certification

EPA Tier 4F, EU Stage IIIA

QSB5-G11 for Rental

Power

-

Torque

-

Certification

EPA Tier 4F, EU Stage IIIA

QSB5-G11 for Rental

Power

-

Torque

-

Certification

EPA Tier 4F, EU Stage IIIA

QSB5-G11 for Rental

Power

-

Torque

-

Certification

EPA Tier 4F, EU Stage IIIA

KTAA19 for Commercial Industrial

Power

-

Torque

-

Certification

N/A

KTAA19 for Commercial Industrial

Power

-

Torque

-

Certification

N/A

GTA8.3G for Commercial Industrial

Power

-

Torque

-

Certification

N/A

GTA8.3G for Commercial Industrial

Power

-

Torque

-

Certification

N/A

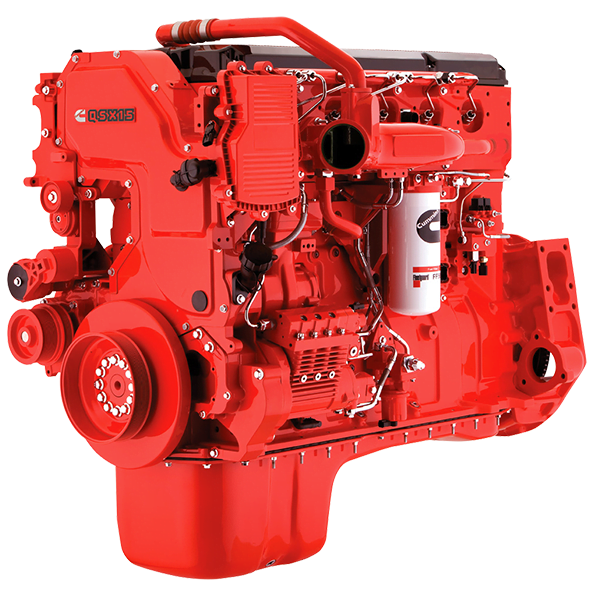

QSX15 for Construction (Tier 4 Interim)

Power

400 - 600 hp

Torque

-

Certification

EPA Tier 4, EU Stage III

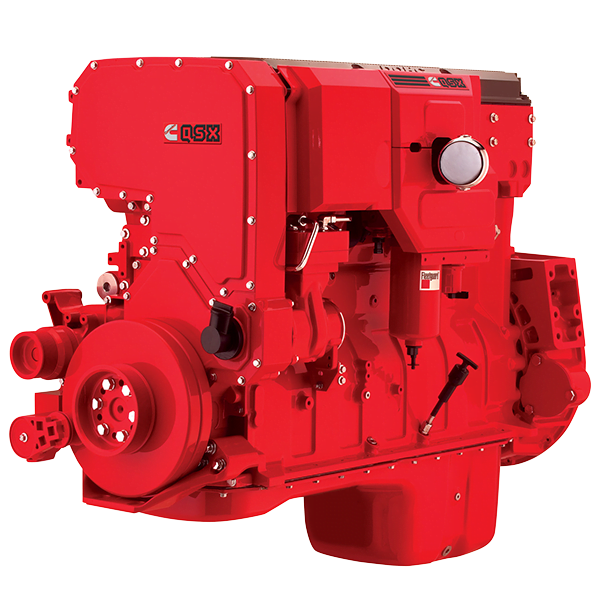

QSX for Construction (Tier 3)

Power

375 - 665 hp

Torque

1346 - 1875 lb-ft

Certification

EPA Tier 3, EU Stage III

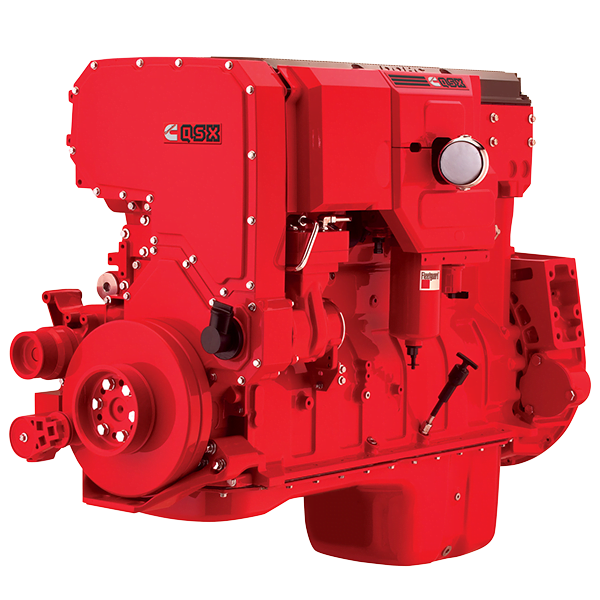

QSX for Industrial Applications

Power

375 - 665 hp

Torque

1346 - 1875 lb-ft

Certification

EPA Tier 3, EU Stage III

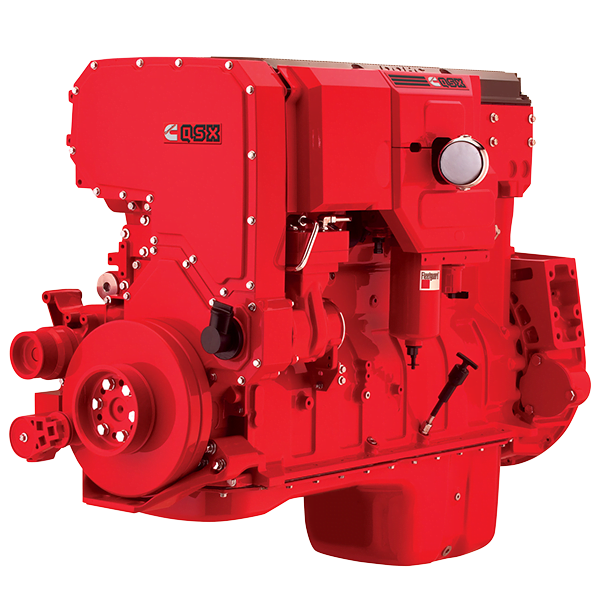

QSX for Construction (Tier 2)

Power

350 - 635 hp

Torque

1182 - 2050 lb-ft

Certification

EPA Tier 2, EU Stage I

QST30 for Oil & Gas

Power

1200 - 1500 hp

Torque

3750 - 4877 lb-ft

Certification

QST30 for Construction (Tier 2)

Power

760 - 1200 hp

Torque

2471 - 3750 lb-ft

Certification

EPA Tier 2, EU Stage I