“Electricity” brings businesses to life, as it powers various activities within a business, from production to administration. Issues such as power outages, fluctuations, drops, or insufficient supply can disrupt critical activities and cause significant business damage.

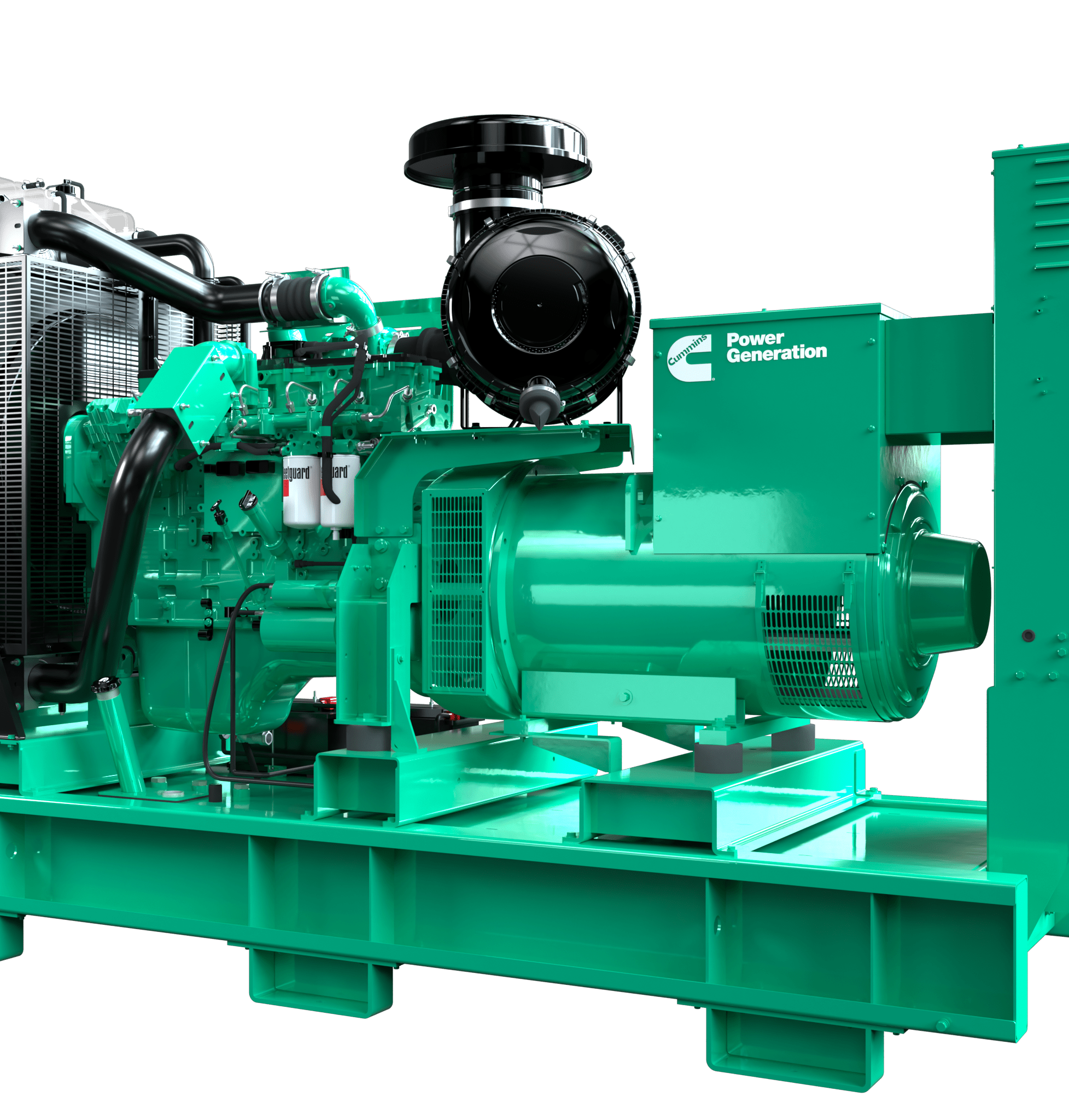

Therefore, power generators are the heart of a business, ensuring that critical activities continue smoothly. Executives and stakeholders are well aware of this and have installed power generators for such eventualities. However, how can you be sure that in times of main power supply issues, the installed power generator will start immediately, providing enough electricity to meet the necessary requirements and maintain high stability that you can rely on throughout the power supply period?

To ensure that power generators operate normally, it depends on two critical factors:

Choosing high-quality power generators with specifications suitable for the intended use

Maintenance of the power generator correctly and regularly by yourself* and certified experts from Cummins

These two factors significantly affect the stability of emergency power supply, especially for businesses and business activities that cannot afford even the slightest risk. This article will focus on the importance of choosing high-quality power generators with specifications suitable for their intended use, to understand the crucial role power generators play in your critical business activities.

*In some cases

What is a Power Generator?

A Power Generator (Genset) or commonly referred to as a generator set (Gen Set), is a device or system that generates electricity by converting mechanical energy into electrical energy using the principle of electromagnetic induction. Currently, it is often used in the industry as a backup power source, both to supplement the main power supply and/or to provide backup power in emergencies, thereby reducing the chance of business damage and production process disruptions in the event of a main power supply failure or malfunction.

Power generators can be divided into several types according to the different needs of the business sector. If divided by engine type, there can be diesel engines and gasoline engines. However, users and operators often prefer diesel-powered generators because they have a longer lifespan, require less maintenance due to well-coordinated internal components, and are highly efficient. They are suitable for heavy industrial use that requires high power, while gasoline engines are usually more complex and suitable for applications that do not require high power, such as residential use.

Moreover, using diesel-powered generators helps business owners and operators reach the break-even point faster and save on expenses significantly because diesel fuel is a product that the government supports in price stabilization, both for producers and for the public consumers at the end of the supply chain.

Considering the electrical system produced, it can be divided into two types: direct current (generators for direct current are called Dynamos) and alternating current (generators for alternating current are called Alternators). For industrial use, alternating current generators are used because of the advantages of alternating current, which has high voltage and is suitable for loads that require a lot of power.

The Importance of Choosing the Right Power Generator for Your Business

"Any brand of power generator... won't do!"

Considering the perspective of business and industrial use, it is evident that there is a high demand for power and often complex and challenging environmental conditions. Therefore, the voltage must be appropriate, continuous, highly stable, and provide enough electricity to meet the necessary requirements during power outages or drops. You will start to see the importance of power generators more clearly, that it’s not just any power generator that will do… but it must be a brand that you can trust and rely on.

Because if the power generator malfunctions even slightly – or cannot operate according to the “necessity” or “sufficient for the demand,” it could mean severe damage to the business or even people’s lives. This article explains the importance of power generators through the perspective of these three businesses: data centers, hospitals, and closed-system livestock farms.

A data center is a building, place, or floor within a building that contains a large number of servers responsible for receiving, sending, storing, and processing massive amounts of data. It supports the activities of various industrial sectors, processing millions of transactions per minute. Installing or choosing an inappropriate power generator, such as one with insufficient capacity for the data center’s needs, or if there are even minor stability issues with the electricity, can cause servers to temporarily or immediately stop working (often referred to as a “system crash”), leading to damages you cannot afford, such as internet system malfunctions, damage to high-value transaction data, important business information, and data that needs constant communication, especially in today’s digital world where businesses and industries rely on online systems for production. This is something you

(whether you are a data center service provider or an IT department server room in a large organization) cannot afford to happen even for a moment.

"For some businesses... even a flicker of electricity is unacceptable!”

Can you imagine which part of the hospital cannot afford a power outage? Our answer would probably be that every place, every floor in the hospital is important, but if we had to choose just one room, it would be the “operating room,” filled with emergencies and life-or-death moments, including lighting, heart rate monitors, life support machines, ventilators, surgical display screens, air systems, and many other electrical medical devices. Additionally, important diagnostic equipment in hospitals, such as MRI machines, and even patient transport elevators, where a slight error of just a fraction of a second from both the supplementary and backup power supply systems could lead to the highest level of damage, which is the “life” of someone who has people waiting with hope.

Another example within the hospital that is equally important and may have a wide impact is the patient data processing system. As known, many hospitals have transitioned from paper and file systems to digital data systems in computers (paperless). A problem with the power supply that causes a drop for just a few seconds, leading to a system crash, would prevent doctors from accessing patient data, knowing their history, complications from previous surgeries, etc. This is not impossible but has happened before, such as cases where doctors could not prescribe medication to patients because they could not access patient data, and the patients themselves could not remember their medication, posing a high risk if one has to “guess” or if the patient “reports the wrong medication name,” because receiving the wrong medication not only does not help treat the illness but can also lead to severe allergic reactions.

"Power outage in a hospital... Do you think it's a big deal?"

When talking about closed-system livestock farming, it implies the need for proper management and consideration for the welfare and living conditions of the animals (who are living beings), not just at the level of 100 or 200, but tens or hundreds of thousands. Therefore, the provision of food and water, lighting and electrical systems, automatic temperature control systems, gas level management in the barn to prevent excessive levels, and hygiene systems are all crucial for every life on the farm. If observed, the systems in a closed-system livestock farm almost entirely depend on electricity. Therefore, when installing a backup electrical system, careful consideration is needed to ensure it can supply electricity appropriately, sufficiently, and cover the entire farm system; otherwise, it could mean significant business damage in the hundreds of thousands to millions.

For those interested in power generators and backup power systems in closed-system farms, you can learn more in the article “Power Generators in Chicken Farms.”

The examples of these three types of businesses mentioned are to illustrate that choosing power generators to supplement the main power supply sufficiently for the demand and for emergency backup power systems requires careful consideration of many factors, starting from the nature of the work and the actual needs at the job site, design, load calculation, installation according to laws and related regulations for the use of power generators, as well as being able to find spare parts when needed, having specialized technicians, and having warranties that give you peace of mind, to reduce the risk or errors that could severely impact the business, lives, and property.

For business owners interested in Cummins Power Generator Solutions

- We offer pre-delivery testing of the machine*

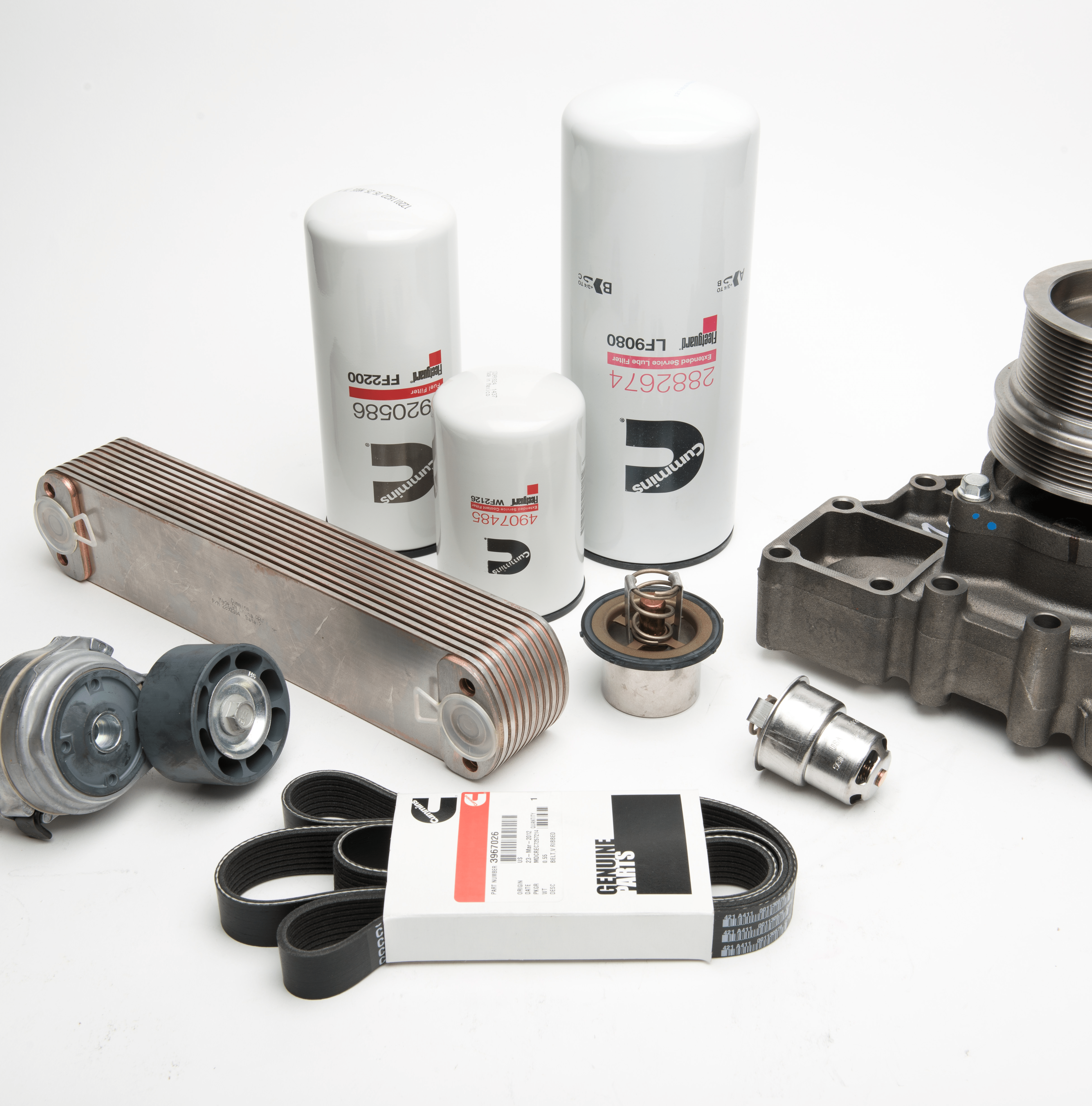

- Guarantee the provision of genuine parts for repairs for at least 10 years*

- Annual maintenance service (on-site Preventive Maintenance) throughout the lifespan*

- In-shop maintenance service at the after-sales service center in Wang Noi, Phra Nakhon Si Ayutthaya, the only standard service center in Thailand certified by Cummins Inc

Don't Forget! Plan the Maintenance of Your Power Generator

In addition to choosing the right power generator for your business, another equally important factor that plays a significant role in the lifespan of the power generator is proper maintenance. Understanding the basic self-inspection guidelines and knowing when to send for repair with expert technicians can help you use the power generator to its full potential, according to its intended lifespan, and minimize the risk of damage to the power generator and electrical equipment at your job site as much as possible, because we know that “anything you buy at a high price, you would want to use it to its fullest value.”

Why Plan the Maintenance of Your Power Generator?

1.Because the use of power generators varies, requiring different care. Power generators with different usage characteristics, such as some machines that operate continuously without rest, and some that are used intermittently, require planned maintenance for different uses and must choose the appropriate approach.

2.To observe and understand the signs of abnormalities in time

When the power generator shows signs of abnormality or some warning signals, you need to know which symptoms or signals indicate possible problems, so you can plan the correct corrective actions according to urgency.

3. To check for abnormalities that cannot be observed by oneself

The problems that may occur with power generators do not always manifest as clear signals. Therefore, manufacturers require regular inspection and maintenance plans for power generators to check for equipment and abnormalities in the machine that you cannot observe by yourself.

Cummins' approach to power generator maintenance is divided into two types:

1.Regular self-inspection and maintenance:

Which are inspections that can be done by oneself daily or weekly (depending on the inspection requirements)

2.Inspections and maintenance that must be handled by the Cummins technician team only (cannot be done by oneself):

These are inspections that require expertise, involve complex technical methods, and require specific testing tools that are high-risk and dangerous. These types of inspections should be performed by skilled technicians from Cummins.

In Summary

Carefully and thoroughly choosing high-quality power generators with specifications suitable for their intended use is a critical factor in protecting your business and business activities in times of main power supply issues. Because a slight malfunction of the backup electrical system, resulting from choosing an inappropriate power generator, could mean significant damage to your business. Therefore, it is crucial to seriously understand the industry and the electrical needs at your business site, as it will determine the specifications of the power generator and related systems appropriately.

If you are interested in power generators and emergency backup power systems specifically for your business, we offer consultation services by expert staff. You can consult us through the additional advice request form, by phone 📞 02-301-7500, and email [email protected].