In 2024, industries worldwide are emphasizing renewable energy and sustainability. This shift encompasses business operations, manufacturing, transportation, and even considerations on consumption patterns.

Cummins, as a leading global manufacturer of generators and engines, has always prioritized and promoted sustainability. Our researchers and engineers are dedicated to designing, innovating, and repeatedly testing to produce Gas Generators that can utilize waste materials from industrial processes as fuel (through fermentation to convert into methane gas). This gas is then fed into the gas generator, producing electrical and thermal energy that industries can reuse.

Does Cummins have Gas Generators? And what types of gas can they use?

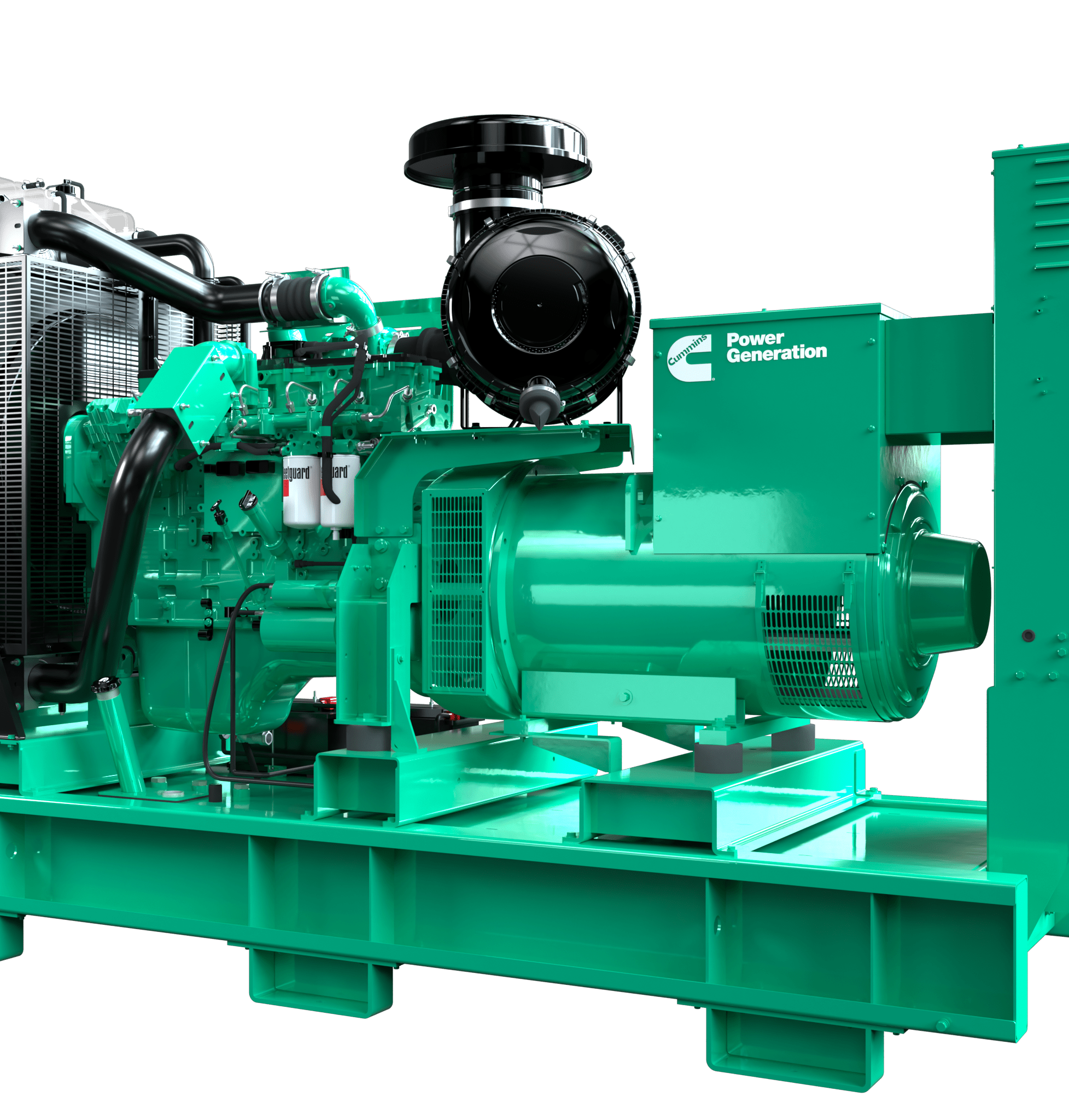

Cummins offers various models and capacities of Gas Generators to cater to different industrial needs. One such model is the Cummins Gas Generator Set HSK78G, which can utilize waste and wastewater from these sources.

- Farm animal manure

- Food scraps and wastewater, waste materials from food processing plants

- Wastewater and food scraps from residential and office buildings

- Wastewater and waste from vegetable oil production plants

- Wastewater and cassava residue from starch production

- Wastewater from ethanol plants

- Energy crops used in power plants

- Community landfills

These materials are then fermented to produce methane gas, which is used as fuel for the gas generator. This process not only reduces fuel and waste disposal costs but also significantly reduces methane emissions, the second most potent greenhouse gas after carbon dioxide, contributing to global warming.

The process begins with collecting animal manure, fresh food scraps, wastewater, palm residue, cassava peels, and corn husks left over from production. These materials undergo methane fermentation and are used as fuel for the generator. This differentiates gas generators from diesel generators, producing electricity and heat as outputs for further use.

The Cummins Gas Generator Set HSK78G is designed and manufactured with advanced technology, featuring replaceable parts and full capacity for electricity and heat production. It meets global emission standards with the lowest exhaust emission level of 250 mg/Nm3 (0.5 g/hp-hr) NOx, eliminating the need for additional waste treatment costs.

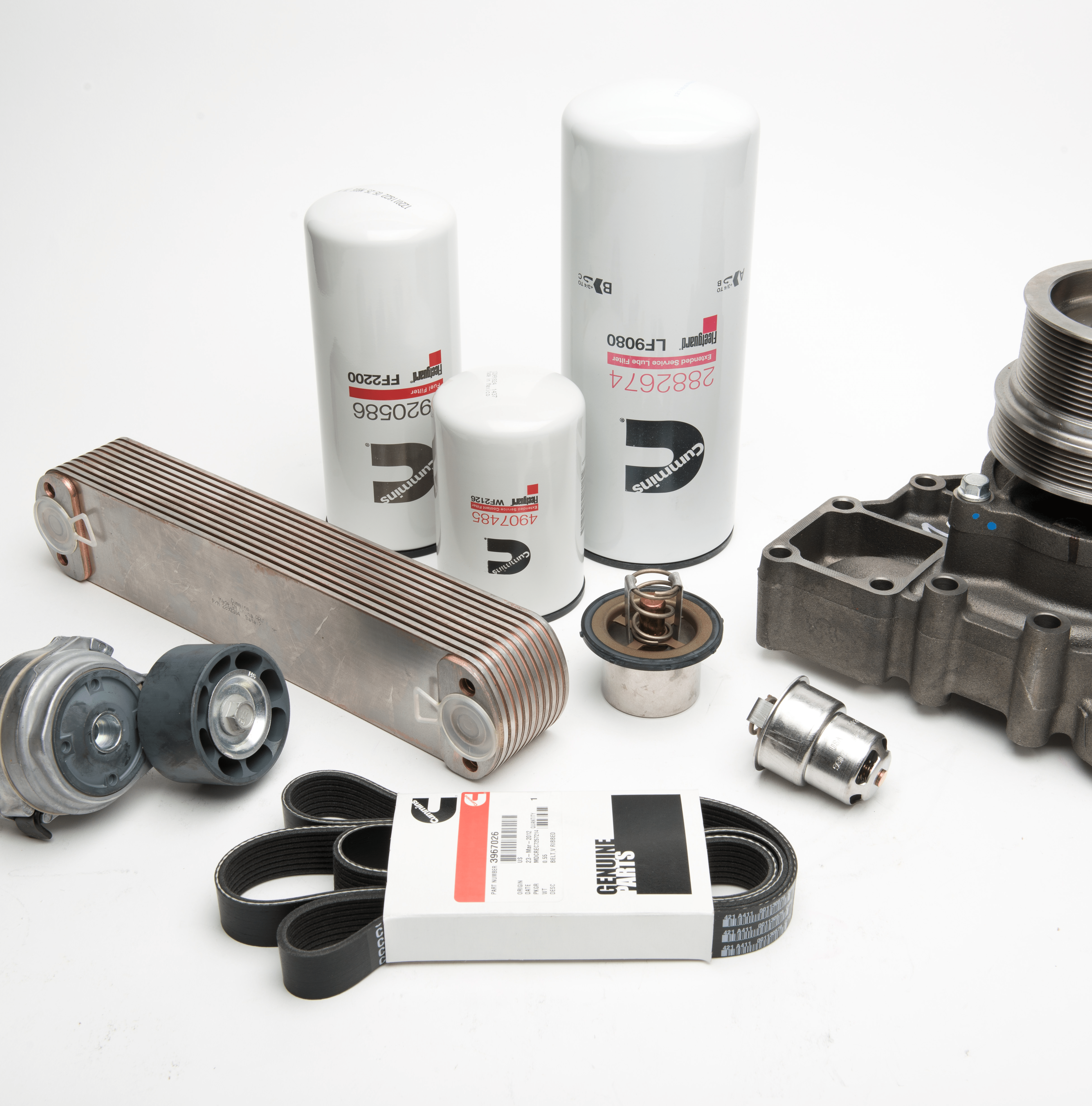

*Provided the generator is used according to the manual, maintained regularly, and genuine Cummins parts and technicians are used.

Is it more cost-effective to perform a Major Overhaul or buy a new Gas Generator?

Currently, most gas generators in the market have reached or are nearing 80,000 hours of operation, necessitating a Major Overhaul, which costs 70-80% of the price of a new generator.

Let’s compare whether to buy or repair clearly.

Comparison table: Major Overhaul of old generator ≠ Buying a new Cummins Gas Genset

*การตัดสินใจทำ Major Overhaul เมื่อพิจารณาเพียงค่าซ่อมเบื้องต้นคุณอาจเห็นตัวเลขที่ถูกกว่าและตัดสินใจซ่อมแทนการซื้อ เพราะลืมคิดถึงค่าใช้จ่ายอีก > = 20% ของ Balance of plant หรือองค์ประกอบส่วนควบอื่น ๆ เพื่อให้เครื่องสามารถทำงานได้เต็มประสิทธิภาพ ซึ่งท้ายที่สุดแล้วค่าใช้จ่ายโดยรวมอาจไม่ได้ถูกอย่างที่คิด

Advantages of using the Cummins Gas Generator

There are four key reasons why the Cummins Gas Generator Set HSK78G is ideal for industries that can use waste materials from production processes as fuel to drive their business:

- Reduces business costs

The Cummins Gas Generator (HSK78G) can utilize waste materials from various industrial processes, such as animal manure, fresh food scraps, wastewater, palm residue, and cassava residue. These materials are fermented into methane gas, which is used as fuel instead of diesel, reducing fuel and waste disposal costs.

- Generates additional income or supports farmers

The residue from fermentation can be used as fertilizer, sold to fertilizer factories, or distributed to neighboring farmers, serving as a form of CSR.

- Encourages profit and social responsibility simultaneously

By reducing waste that generates methane, the second most potent greenhouse gas after carbon dioxide, a significant contributor of global warming, the brand image is enhanced as a socially responsible profit-seeking organization.

- Reduces pollution

An additional benefit of using a gas generator is the reduction of toxic gas emissions, such as carbon dioxide (CO2) and methane (CH4), from animal manure and industrial wastewater. Organizations emitting less carbon dioxide than the set threshold can sell the surplus as Carbon Credits to other organizations or the carbon credit market.

Which industries are suitable for Gas Generators?

Industries where Gas Generators are suitable for electricity production and maximizing the use of waste materials include:

- Livestock farms

- Seafood processing plants

- Cassava starch production plants

- Energy crop power plants

- Biogas production plants from energy crops

- Community waste disposal plants

- Ethanol industry

- Palm oil industry

- Factories with natural gas pipeline systems

"Cummins Gas Generators

help your business grow sustainably"

Reasons to buy Cummins Gas Generators from Cummins DKSH (Thailand)

- We are the only Authorized Distributor in Thailand.

- Gas Generators are researched, developed, and manufactured with modern technology by Cummins Inc’s researchers, engineers, and factories.

- Parts, components, engine oil, and chemicals are readily available in the market.*

- Maintenance technicians and plans are suitable for the heavy and light work demands of today’s industries.

- Emissions compliance with environmental and urgent global warming mitigation requirements.

Interested in Cummins Gas Generators? For more information, contact Cummins DKSH (Thailand) at 02-301-7500 or click the button below.