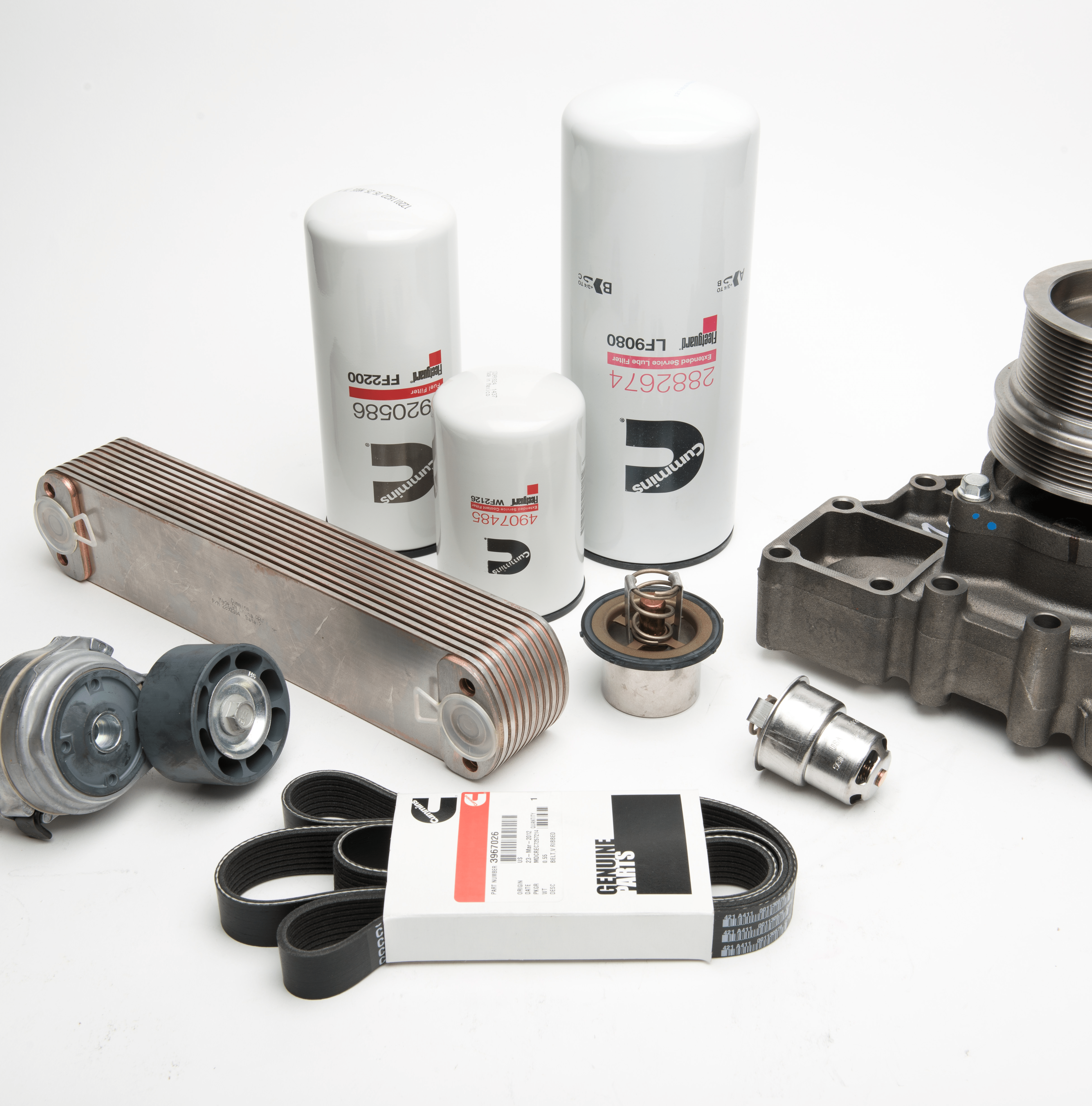

When it comes time to replace parts in engines or generators due to wear and tear, many of us might decide to opt for Non-Genuine parts instead of Genuine Cummins parts simply because they seem interchangeable and are much cheaper.

"But did you know that the initial decision to purchase cheaper Non-Genuine Parts can lead to serious damage

to both the equipment and its lifespan, and could even pose dangers to the operators?

In the end, it's just that... you won't see it happening right away"

Whether you are setting the standards for a job/project, a project manager, a contractor, or an operator on-site, understanding the difference between “Genuine Cummins Parts and Non-Genuine parts” is crucial because this is a way to extend the life of engines and generators, ensuring a return on investment and optimal performance without risking operational interruptions, delays, and enhancing safety for operators.

In this article, we will explain the differences between Genuine Cummins Parts and counterfeit parts (or what the market understands as “Non-Genuine Parts”. Let’s see why choosing genuine parts is so important for your high-value engines and generators.

The problems caused by using Non-Genuine Parts, and the importance of using Genuine Cummins Parts

We all know that using Genuine Cummins Parts is the best choice, but many still opt for Non-Genuine Parts despite knowing that they could eventually lead to damage. This might be due to the attractive lower price or possibly due to misinformation from sellers claiming

“they are the same size and design, there’s no difference, they work just the same.”

“Just because it fits ≠ it functions effectively as Genuine Cummins Parts”

Judging by size or even the ability to fit a part perfectly does not mean it will function identically. There are many other critical factors and components to consider, which often lead to problems after some time of use. Many case studies have shown that this can cause significant damage to the equipment and its users, making it difficult to rectify.

Besides size, what other factors should you consider before deciding to purchase a part?

To give you a clearer picture and to avoid these risks yourself, let’s look at some concrete examples.

The disadvantages of using Non-Genuine Cummins Parts

1. Abnormal operation of the engine/generator due to using Non-Genuine Parts

One common issue with parts not designed and engineered correctly is that the materials used, the manufacturing process, and the shape of the parts cannot withstand the actual operating conditions of the engine and generator.

For example, engine connecting rods, which work under heavy loads, high compression, vibrations, and constant high temperatures, will definitely fail when using Non-Genuine Parts. Starting from the inability to compress air and fuel efficiently, leading to severe engine damage.

When genuine Cummins connecting rods fail, they are designed to break in a way that stops the connection between parts and the engine operation, controlling the spread of damage and ensuring safety.

In consecrated and that parts may bend, twist, or warp, allowing the engine to continue operating under abnormal conditions, leading to further damage to other parts, such as the crankshaft bending, cylinder liners getting scratched, and escalating the damage beyond what should have occurred.

2. Reduced fuel efficiency

Using Non-Genuine Parts leads to poorer fuel efficiency, resulting in higher fuel costs. Initially, you might save money by purchasing cheaper Non-Genuine Parts, but you end up paying more for fuel every day of operation.

For instance, genuine Cummins fuel injectors are designed specifically for the application or job and according to the performance (load) requirements of each engine, ensuring precise fuel delivery, optimal spray patterns for combustion, and maximum efficiency throughout their lifespan. Genuine parts not only help achieve the desired power output but also control and reduce emissions.

In contrast, counterfeit or Non-Genuine fuel injectors often fail to deliver fuel in the fine mist required for optimal combustion as designed by Cummins, leading to inefficient fuel use, increased costs, reduced engine power due to incomplete combustion, and higher emissions.

3. Increased emissions

Let’s delve deeper into this aspect. In today’s business operations, ignoring emissions is not an option. The business world now faces stricter regulations on emissions, clear directives, and penalties that can negatively impact businesses, such as product bans from polluting businesses, campaigns against supporting irresponsible businesses, and being scrutinized by consumers on whether the business keeps its promises, as Cummins does with its commitment to creating environmentally friendly innovations.

Read more at: https://www.cummins.com/company/esg/environment

However, the intention to protect the environment and our world sometimes does not achieve the desired outcome simply because the engine/generator uses non-standard or non-recommended filters, whether for water, oil, or air.

Because non-standard filters, not designed specifically for Cummins engines/generators with the correct size, properties, and quantity as specified by genuine Cummins specifications, struggle to filter substances effectively. Direct consequences of using counterfeit or Non-Genuine filters include sediment slipping into the combustion chamber, reducing performance, causing clogs, and incomplete combustion due to poor filtration, leading to higher emissions than normal.

Besides leading you to believe that “you’re not getting the quality worth your money,” in some cases, it may result in fines according to regulations, loss of tax deduction rights, and worst of all, damage to the reputation and image of the organization as promised.

4. Danger to operators

Last but not least, and most importantly, beyond not getting the performance worth your money, is the unseen danger from using counterfeit or Non-Genuine Parts. These parts are inside the engine and generator, and when operating, abnormalities, high temperatures, clogs, and deformations may be forming (invisible from the outside) and you will only realize when it leads to significant visible damage, and worst of all, to dangerous and unsafe working conditions for operators, which you might not be able to manage… All starting from the thought that “there’s no difference, they work just the same.”

Why is it good to buy Genuine Cummins Parts?

What makes Genuine Cummins Parts good?

The role of new parts is to replace old, damaged ones to ensure they function as intended and work seamlessly with other components. Engines/generators maintained and replaced with Genuine Cummins Parts allow you to be confident in various aspects, as follows:

- Reliable: Because Genuine Cummins Parts are engineered and designed specifically for certain engines /generators, using materials that have been rigorously tested, and produced under Cummins’ controlled standards at every step, you can be assured that the parts will work together perfectly, helping your business run smoothly.

- High performance and durability: Using genuine parts is a key factor in ensuring your engine and generator perform optimally, achieve the desired power, reduce downtime due to repairs, extend their lifespan, and keep your business running every day.

- Full warranty coverage: When you use genuine machines and parts, repaired by our team, you can rest assured that you will receive full warranty coverage, whether for parts or repair work from Cummins DKSH (Thailand).

- Value for money: Because value for money, cost-effectiveness, and getting what you paid for can only be achieved when you can use the expensive engine/generator you purchased to progress as desired, pay only the necessary fuel costs, repair when maintenance is due, stop for maintenance only when necessary, get the power you paid for, and use under all these conditions… for as long as possible.

Using Genuine Cummins Parts is the only way to ensure proper operation of your engine and generator, long service life, value for money, safety, and confidence for you, your business, your employees, and your customers. It means smooth business operations, happy employees, and confident customers.

Summary

"Whether to use genuine or Non-Genuine Parts, you can't just consider the price!!"

Deciding between Genuine Cummins Parts and Non-Genuine Parts based solely on which is cheaper… is not enough. You must consider safety, confidence, reliability when the machine operates, performance, getting the power you need, and also consider the potential business interruptions, cost damages, and customer confidence.

Distinguishing between Genuine Cummins Parts and counterfeit or Non-Genuine Parts is very easy, just make sure to purchase from Cummins DKSH (Thailand), the sole official importer and distributor in Thailand, or from our certified dealers. This way, you can be confident that you are using the best for your engine and generator.

*If your engine/generator is maintained according to the service intervals or operating hours as recommended in the manual and by us

**Please check the warranty conditions with the sales representative managing your account

***Please check the list of dealers from us before making a purchase

Only Buy Cummins Engines, Power Generators, Spare Parts and Aftermarket Services from Cummins Authorized Distributors. Contact us today or call 02-301-7500 or click the button below.