PRODUCT Detail

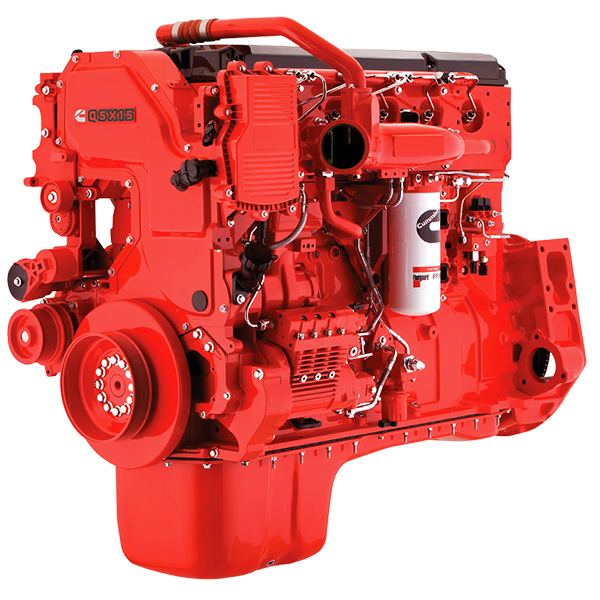

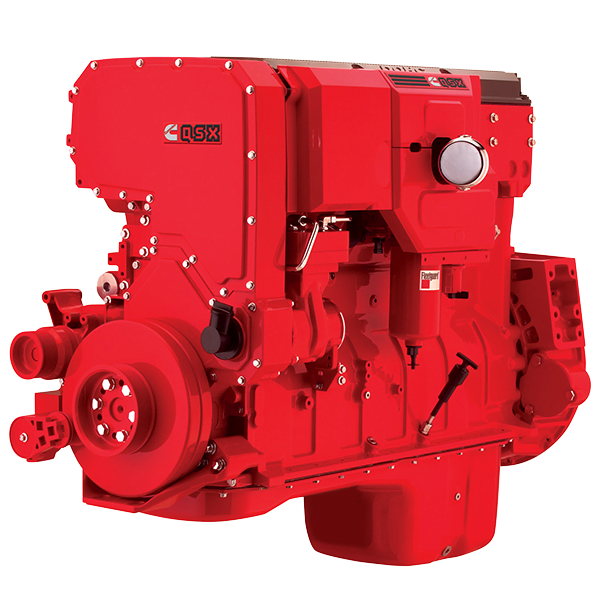

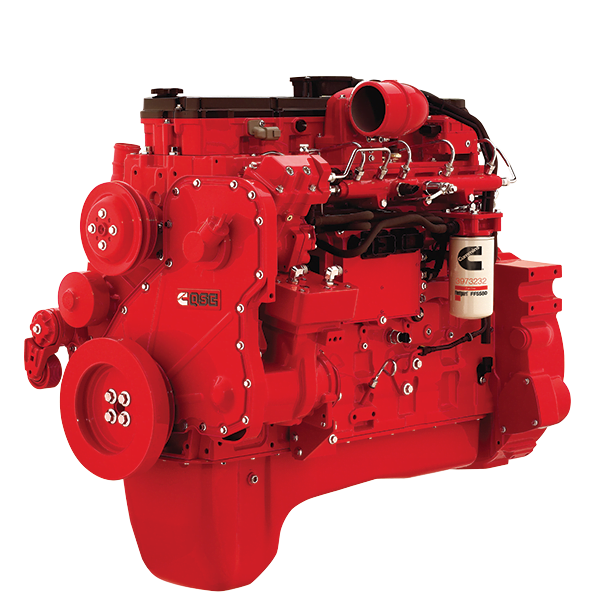

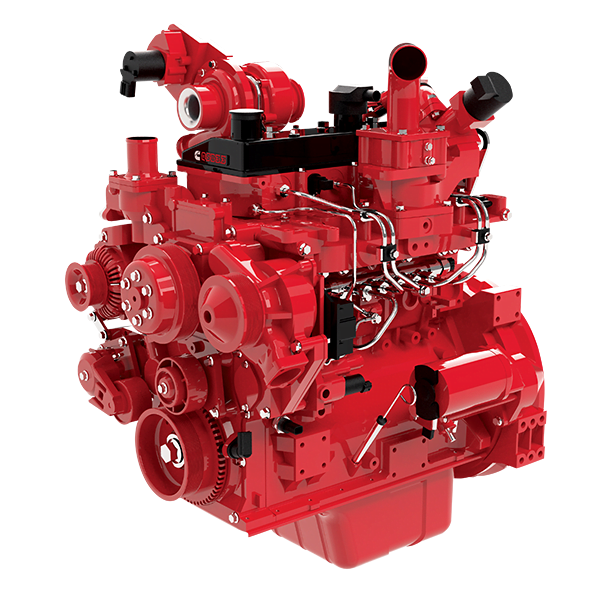

The QSX15 for 2011 incorporates Cummins proven technology enablers to meet EPA Tier 4 Interim and EU Stage IIIB low emissions standard. With ratings from 400 – 600 hp (298 – 447 kW), the QSX15 will achieve up to 5 percent better fuel efficiency*, lowering your cost of operation and improving your bottom line.

The QSX15 achieves these very low emission levels by using our proven cooled Exhaust Gas Recirculation (EGR) and Cummins Particulate Filter. Both systems have been specifically developed for industrial applications delivering premium performance and durability you can depend on.

The Tier 4 Interim and Stage IIIB 15-liter engine incorporates Cummins Xtra-High Pressure Injection (XPI) fuel system enabling very high fuel injection pressure across all engine rpm speeds, providing cleaner combustion and improved engine response. Together, the fuel system and Cummins Variable Geometry Turbo (VGT™) provide optimal performance with a precise match of engine rpm and load demands.

Additional performance-enhancing features include Cummins Direct Flow air filtration system providing a 35 percent smaller installation profile than radial air filters, plus improved filtration efficiency and a crankcase ventilation system with a highly-efficient coalescing filter. Cummins Electronic Control Module manages all components for a completely integrated system providing the impressive reliability and durability and long maintenance intervals you expect from the world’s Tier 4 technology leader.

All backed by the best customer support in the business.

Want to know what up to 5 percent better fuel efficiency will mean for your bottom line? Visit the Fuel Duel page to find out.

*Depending on rating and installation optimization.

| Engine Type | In-Line, 6-Cylinder |

| Displacement | 15 L* (915.4 cu in) |

| Advertised Horsepower | 400-600 hp (298-447 kW) |

*L = Liters / Litres

Direct Flow Air Filtration System – Specifically developed for Tier 4 platforms to provide a smaller, more flexible installation package and higher air filtration efficiency.

XPI Fuel System – Delivers a precise quantity of fuel at ultra-high pressures. This, together with more robust electronic engine controls, enables multiple injection events per cycle.

Variable Geometry Turbocharger (VGT™) – Enhanced response and control with electric actuation for an infinite adjustment, providing exact boost across the operating range. Sliding-nozzle design increases reliability, durability.

Fully Integrated Electronic Controls – A single, higher-capacity Electronic Control Module (ECM) controls everything from air intake to exhaust aftertreatment for peak performance.

Cooled Exhaust Gas Recirculation – Lowers combustion temperatures for reduced emissions and optimized fuel efficiency.

Cummins Particulate Filter – Fully integrated for uncompromising performance, reliability. Removes over 90% of particulate matter and is specifically developed to withstand severe shock loads and vibrations typical of industrial applications.

Crankcase Ventilation System – Prevents crankcase emissions escaping from the engine with a highly-efficient coalescing filter. Also, eliminates oil mist and tiny oil droplets to maintain clean engine operating conditions.

Lowest Cost Of Operation – Reduced maintenance, long service intervals and the best fuel efficiency of any engine in its class add up to superior lifetime value.

ดาวน์โหลดโบร์ชัวร์สินค้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ

similar products

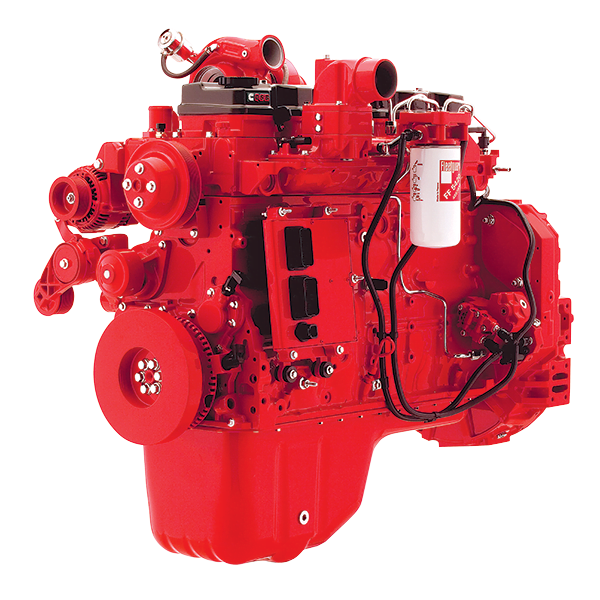

QSX for Agriculture (Tier 3)

Power

375 - 665 hp

Torque

1346 - 1875 lb-ft

Certification

EPA Tier 3, EU Stage III

QSX for Agriculture (Tier 2)

Power

350 - 635 hp

Torque

1182 - 2050 lb-ft

Certification

EPA Tier 2, EU Stage I

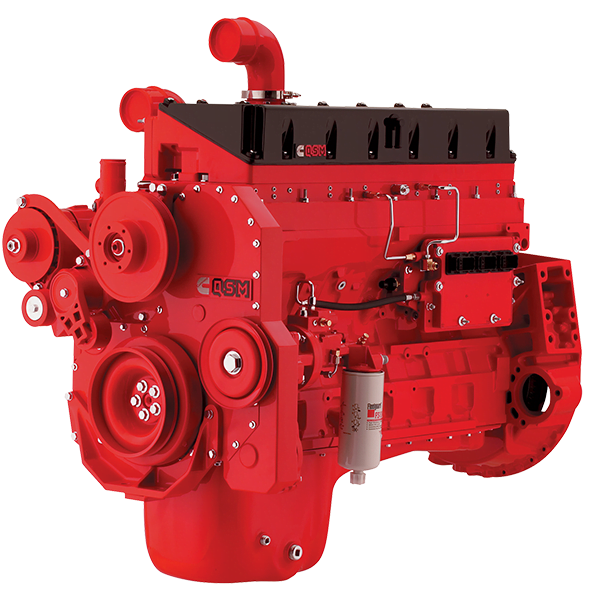

QSM for Agriculture (Tier 3)

Power

290 - 400 hp

Torque

1150 - 1400 lb-ft

Certification

EPA Tier 3, EU Stage III

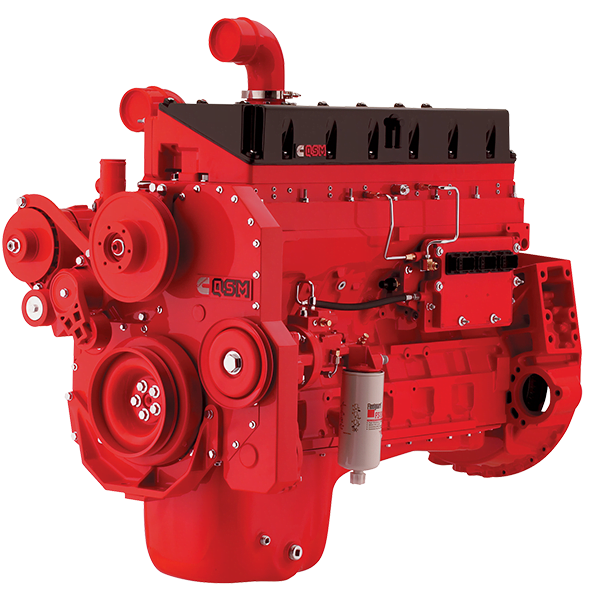

QSM for Agriculture (Tier 2)

Power

250 - 400 hp

Torque

845 - 1400 lb-ft

Certification

EPA Tier 2, EU Stage I

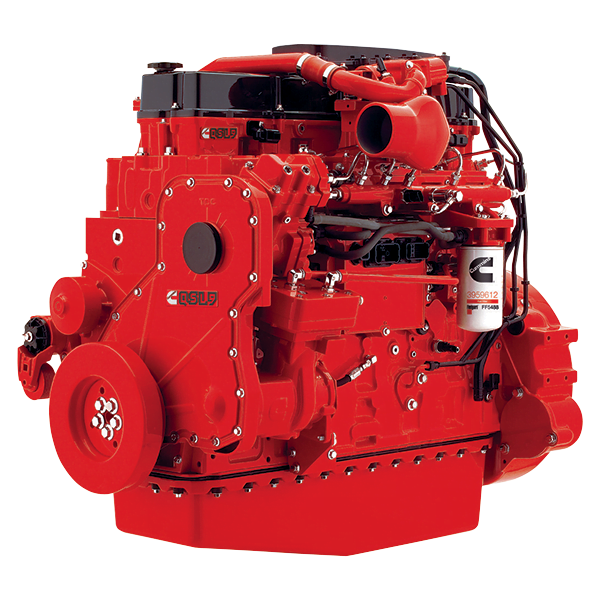

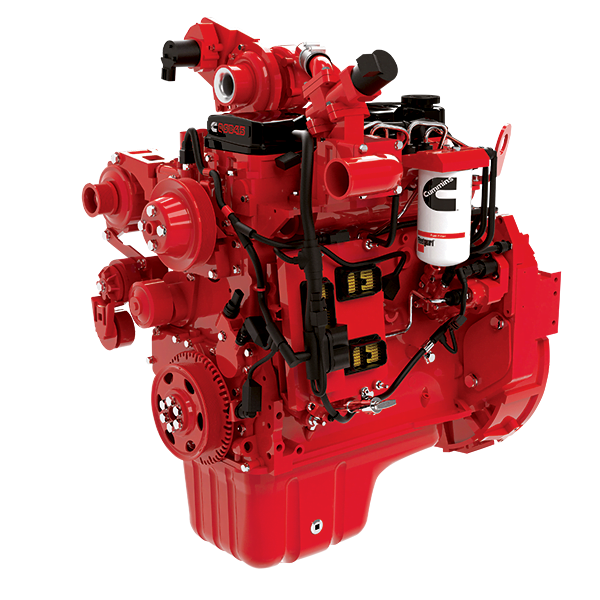

QSL9 for Agriculture (Tier 4 Interim)

Power

230 - 400 hp

Torque

675 - 1200 lb-ft

Certification

EPA Tier 4, EU Stage III

QSL for Agriculture (Tier 3)

Power

280 - 365 hp

Torque

950 - 1113 lb-ft

Certification

EPA Tier 3, EU Stage III

QSK23 for Agriculture (Tier 2)

Power

760 - 950 hp

Torque

2558 - 2897 lb-ft

Certification

EPA Tier 2, EU Stage I

QSK19 for Agriculture (Tier 2)

Power

755 - 800 hp

Torque

2275 - 2275 lb-ft

Certification

EPA Tier 2, EU Stage I

QSC for Agriculture (Tier 3)

Power

205 - 305 hp

Torque

675 - 1020 lb-ft

Certification

EPA Tier 3, EU Stage III

QSC for Agriculture

Power

-

Torque

-

Certification

QSB6.7 for Agriculture (Tier 3)

Power

133 - 275 hp

Torque

431 - 730 lb-ft

Certification

EPA Tier 3, EU Stage III

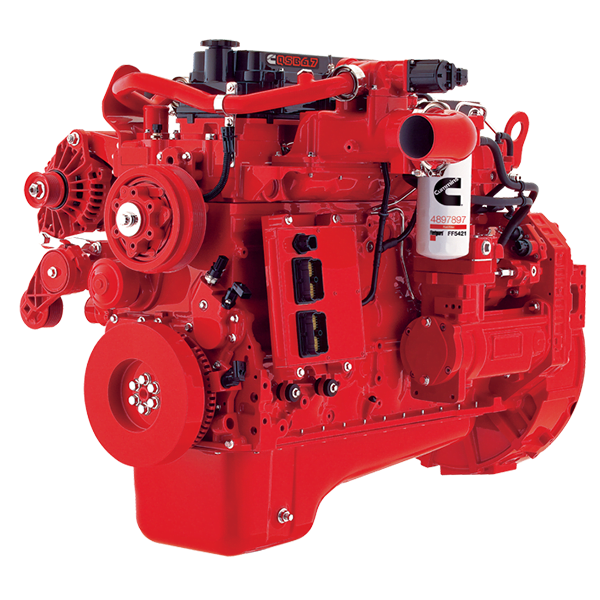

QSB6.7 for Agriculture (Tier 4 Interim)

Power

146 - 300 hp

Torque

485 - 730 lb-ft

Certification

EPA Tier 4, EU Stage III

QSB4.5 for Agriculture (Tier 4 Interim)

Power

110 - 168 hp

Torque

347 - 460 lb-ft

Certification

EPA Tier 4, EU Stage III

QSB3.3 for Agriculture (Tier 4 Interim)

Power

85 - 120 hp

Torque

277 - 306 lb-ft

Certification

EPA Tier 4, EU Stage III