PRODUCT Detail

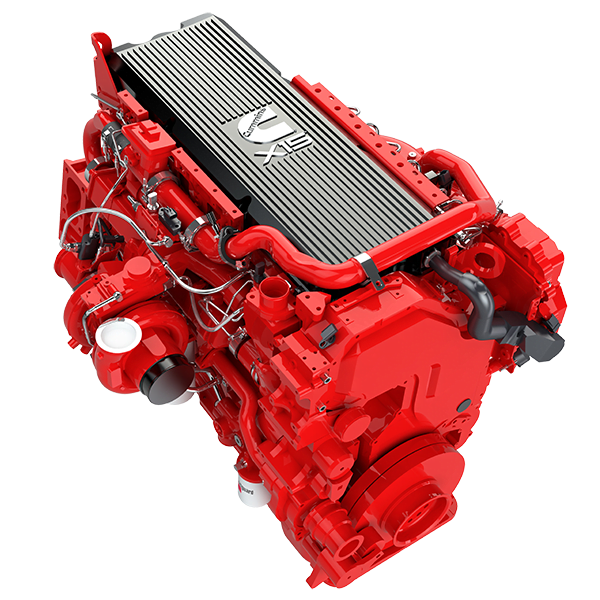

ISX12. Better. From Morning To Night.

Cummins ISX12 builds on the legacy of the ISM and proven technology of the ISX15 to deliver better fuel economy, performance, reliability and durability. It has more horsepower and more torque, plus stronger acceleration – all in a compact design. It achieves near-zero emissions and reduces noise output. So no matter what kind of equipment you run it in, the ISX12 has the power to accomplish every task better. From morning to night.

Optimized calibrations have resulted in significant fuel economy gains for the ISX12. Fuel economy has improved up to 5% in regional haul applications and up to 12% in vocational applications versus the ISX11.9.

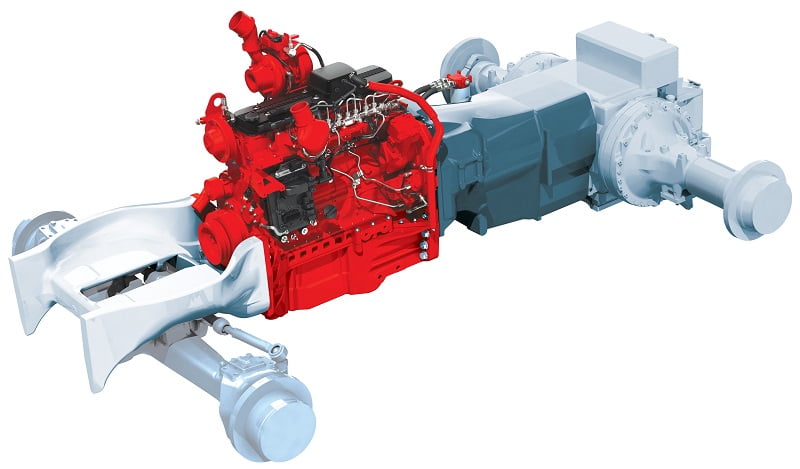

The ISX12 is an exceptional choice for vocational applications, with a high power-to-weight ratio and 800 lb-ft (1085 N•m) of clutch engagement torque. Eight vocational and five refuse ratings are available, along with integrated Rear Engine Power Take-Off (REPTO), Front Engine Power Take-Off (FEPTO) and a choice of hydraulic drive options. This combination of power and flexibility is an ideal choice for rear- and front-pouring mixers as well as dump trucks and refuse haulers.

The ISX12 has the power range to meet the needs of regional hauling and LTL distribution operations. Standard ratings range from 310 hp to 425 hp (231-317 kW). SmartTorque ratings unleash higher torque in the two top gears so that drivers can climb steep hills with fewer downshifts.

Cummins is the only engine manufacturer to design and develop, manufacture and support every component from the air intake to the exhaust aftertreatment in a totally integrated system.

The XPI fuel system is capable of the highest injection pressures in the industry, with a common-rail design that delivers strong performance independent of engine speed. The integrated system of the ISX12 also includes a VGT™ Turbocharger custom-built by Cummins Turbo Technologies.

The Cummins Aftertreatment System on the ISX12 combines a proprietary Cummins Particulate Filter with our Selective Catalytic Reduction (SCR) technology, functioning as a single unit. Designing and building the package in-house allows Cummins to calibrate the engine for optimum performance and near-zero emissions. The high efficiency of the aftertreatment frees the engine to generate higher horsepower while also saving fuel. Improved fuel economy not only lowers fuel consumption – it also reduces greenhouse gas (GHG) emissions.

And that’s just the start of all the features the ISX12 has to offer. Every element has been designed and manufactured to optimize performance and minimize maintenance for superior driveability.

All backed by the best customer support in the business.

Considering a Cummins engine purchase? For more information including pricing and additional technical information, please contact your Cummins representative. If you need help finding a representative, the Cummins Sales and Service Locator tool can help.

| Advertised Horsepower¹ | 310-425 hp | 231-317 kW |

| Peak Torque | 1150-1650 lb-ft | 1559-2237 N•m |

| Governed Speed | 2100 rpm | |

| Clutch Engagement Torque | 800 lb-ft | 1085 N•m |

| Number of Cylinders | 6 | |

| Oil System Capacity | 11 U.S. gallons | 45.4 liters |

| System Weight | 2,888 lb | 1,310 kg |

| Engine (Dry) | 2,666 lb | 1,209 kg |

| Aftertreatment System* | 222 lb | 101 kg |

*Increase over standard muffler and does not include chassis OEM-supplied components

XPI Fuel System – Delivers a precise quantity of fuel at ultra-high pressures. This, together with more robust electronic engine controls, enables multiple injection events per cycle.

Compact Design – Compact and powerful, with plenty of torque to pull every load while delivering optimum fuel economy. It shares many major components with the ISX15, so it’s strong enough to handle virtually any application.

VGT™ Turbocharger – Enhanced response and control with electric actuation for infinite adjustment, providing exact boost at any rpm. Sliding-nozzle design increases reliability and durability.

Cooled EGR – Next-generation system lowers combustion temperatures for reduced emissions and optimized fuel economy.

Fully Integrated Electronic Controls – A single, higher-capacity Electronic Control Module (ECM) controls everything from air intake to exhaust aftertreatment for peak performance and near-zero emissions.

Cummins Aftertreatment System – The proven Cummins Particulate Filter reduces particulate matter by over 90%. In 2010 it is combined with Cummins Selective Catalytic Reduction (SCR) to meet emission standards while maintaining best-in-class performance, reliability and durability.

ดาวน์โหลดโบร์ชัวร์สินค้า

ลงทะเบียนเครื่องยนต์และเครื่องกำเนิดไฟฟ้าของคุณวันนี้ เพื่อรับข้อมูลล่าสุดเกี่ยวกับสินค้า

ข้อมูลทางเทคนิค การซ่อมบำรุง และการขอคำแนะนำสำหรับคุณ

similar products

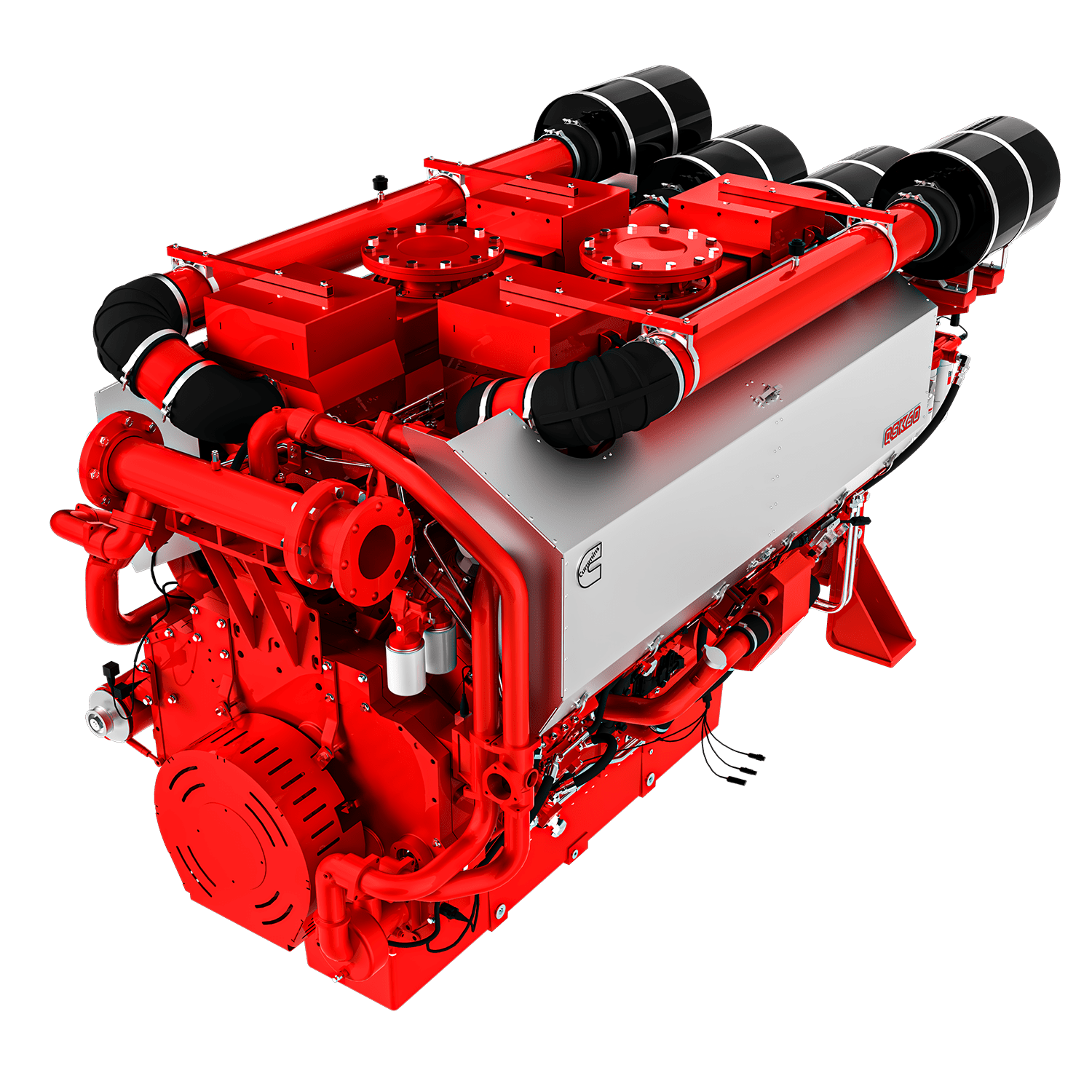

COMMERCIALQD 11HDKBN-6000C

Power

Torque

Certification

X15N (2024)

Power

400 - 500 hp

Torque

1450 - 1850 lb-ft

Certification

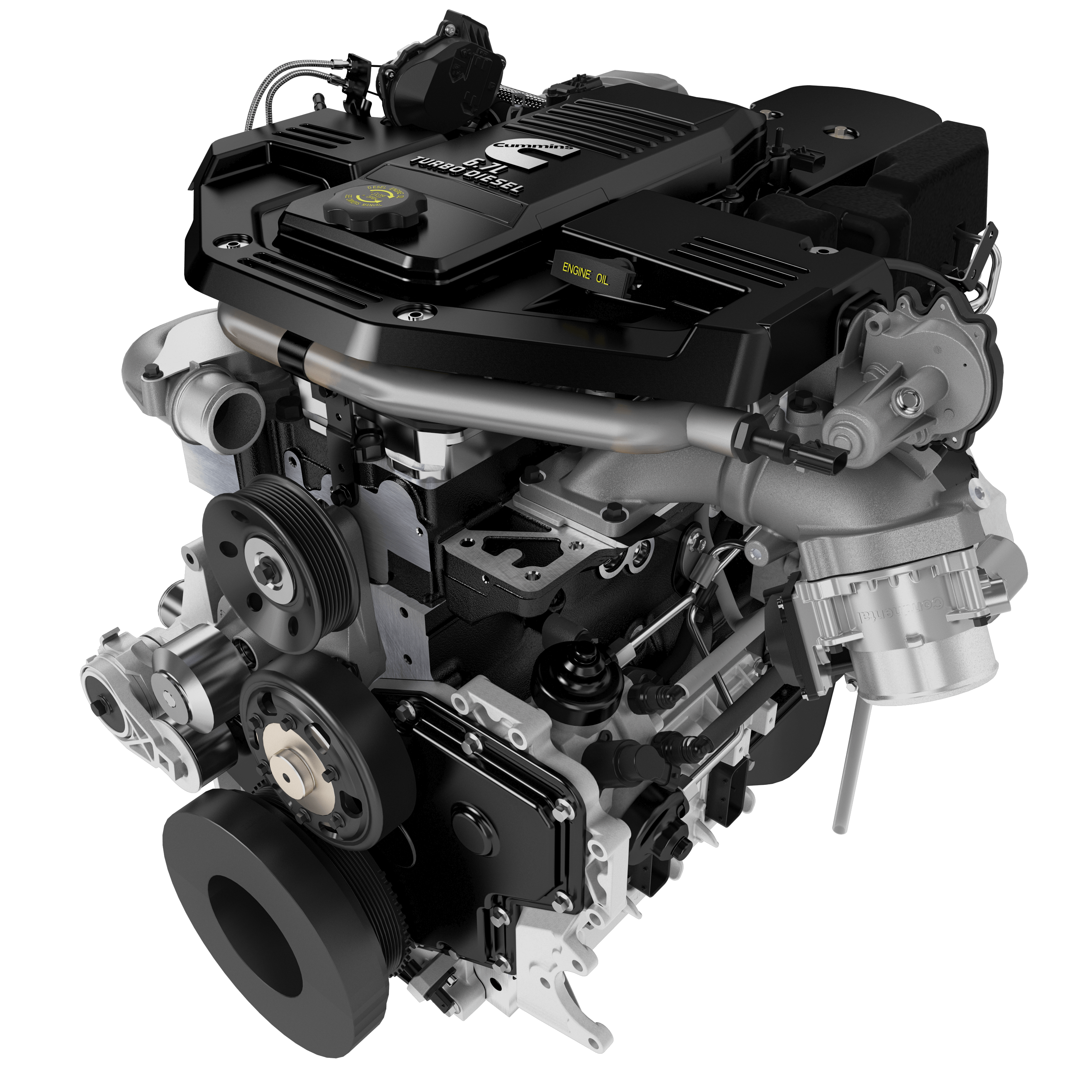

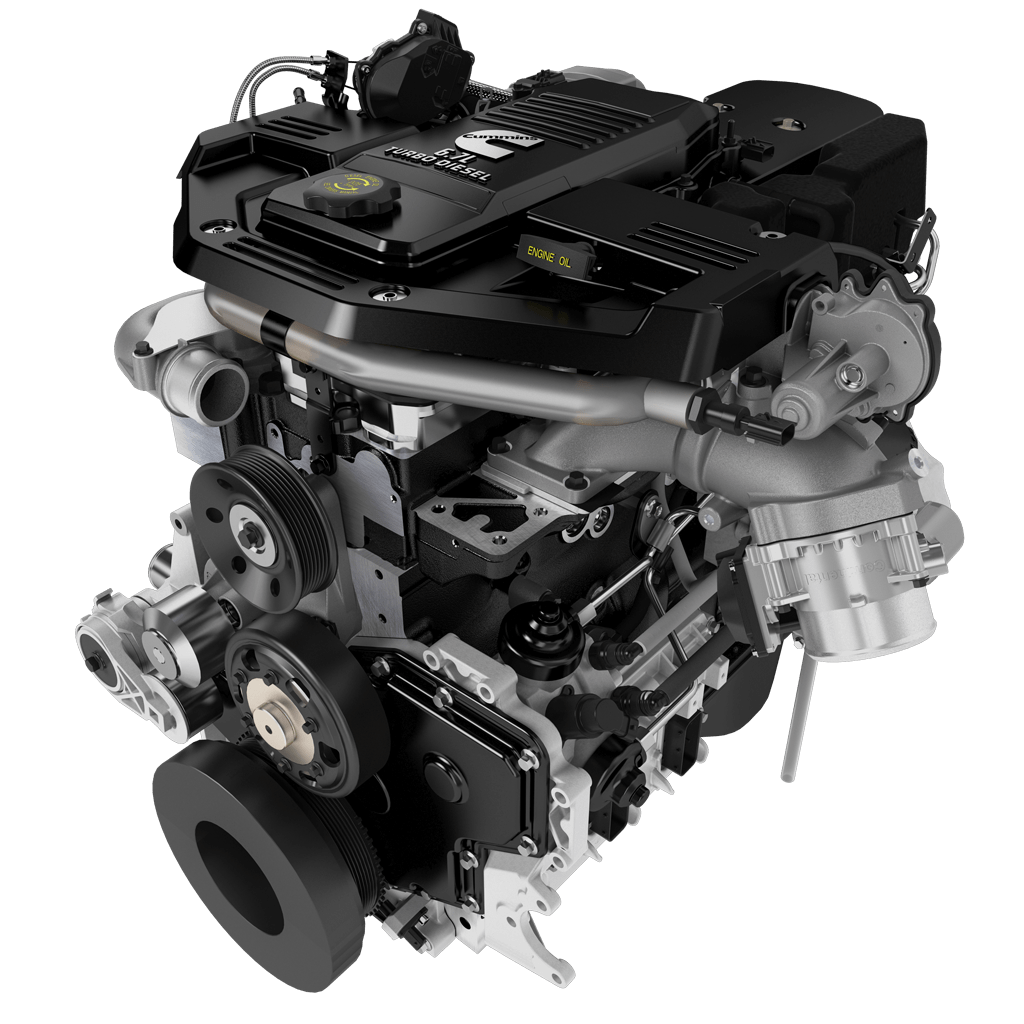

Remanufactured Cummins Turbo Diesel

Power

325 - 385 hp

Torque

610 - 930 lb-ft

Certification

B6.7 Structural Engine

Power

155 - 326 hp

Torque

650 - 1014 lb-ft

Certification

EU Stage V, EPA Tier 4F

6.7L Cummins Turbo Diesel (2018) for Chassis Cab

Power

320 - 325 hp

Torque

650 - 750 lb-ft

Certification

EPA 2018

6.7L Cummins Turbo Diesel (2019) for Chassis Cab

Power

360 - hp

Torque

800 - lb-ft

Certification

EPA 2018

F4.5 Structural Engine

Power

130 - 160 hp

Torque

476 - 476 lb-ft

Certification

EU Stage V, EPA Tier 4F

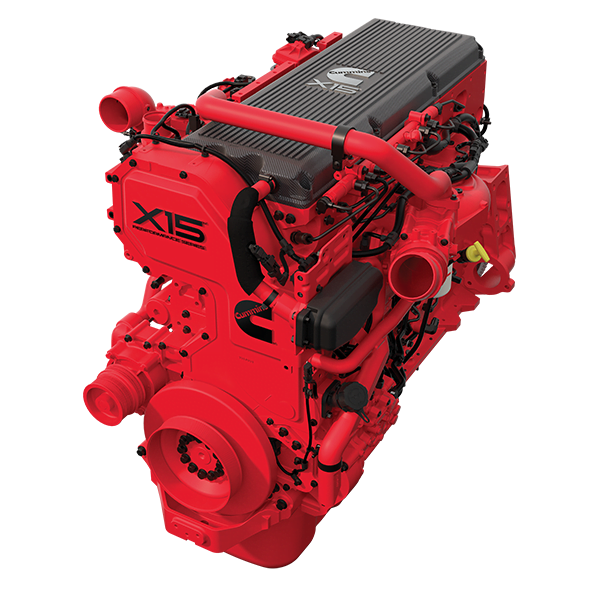

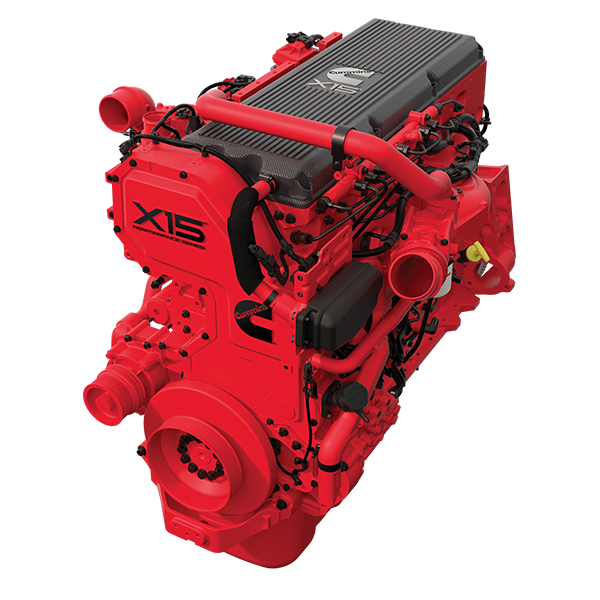

X15 Performance Series (2017)

Power

485 - 565 hp

Torque

1650 - 2050 lb-ft

Certification

EPA 2017

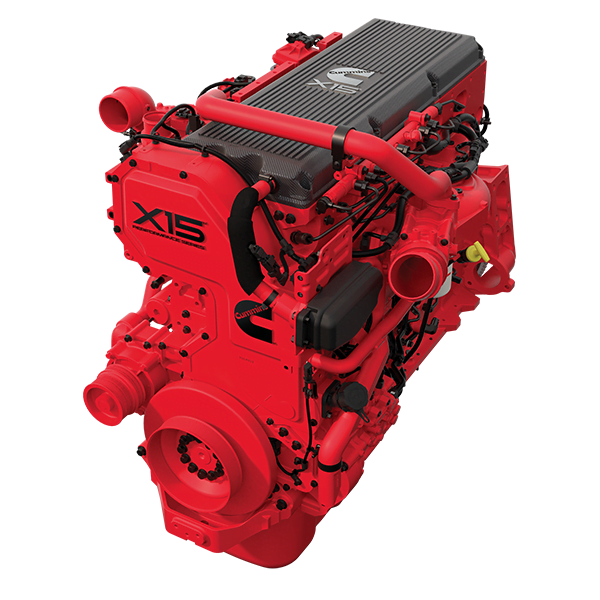

X15 Performance Series for Heavy-Duty Truck (2017)

Power

485 - 565 hp

Torque

1650 - 2050 lb-ft

Certification

EPA 2017

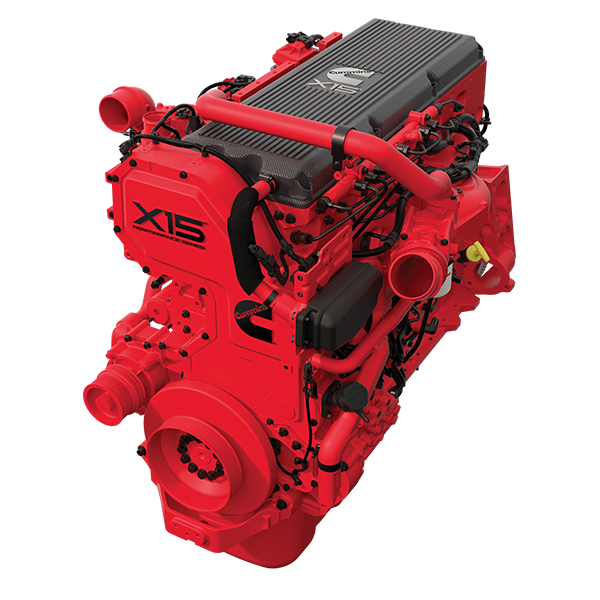

X15 Performance Series for Fire & Emergency (2017)

Power

505 - 565 hp

Torque

1850 - 1850 lb-ft

Certification

EPA 2017

X15 Performance Series for TEMs & Body Builders

Power

485 - 565 hp

Torque

1650 - 2050 lb-ft

Certification

EPA 2017

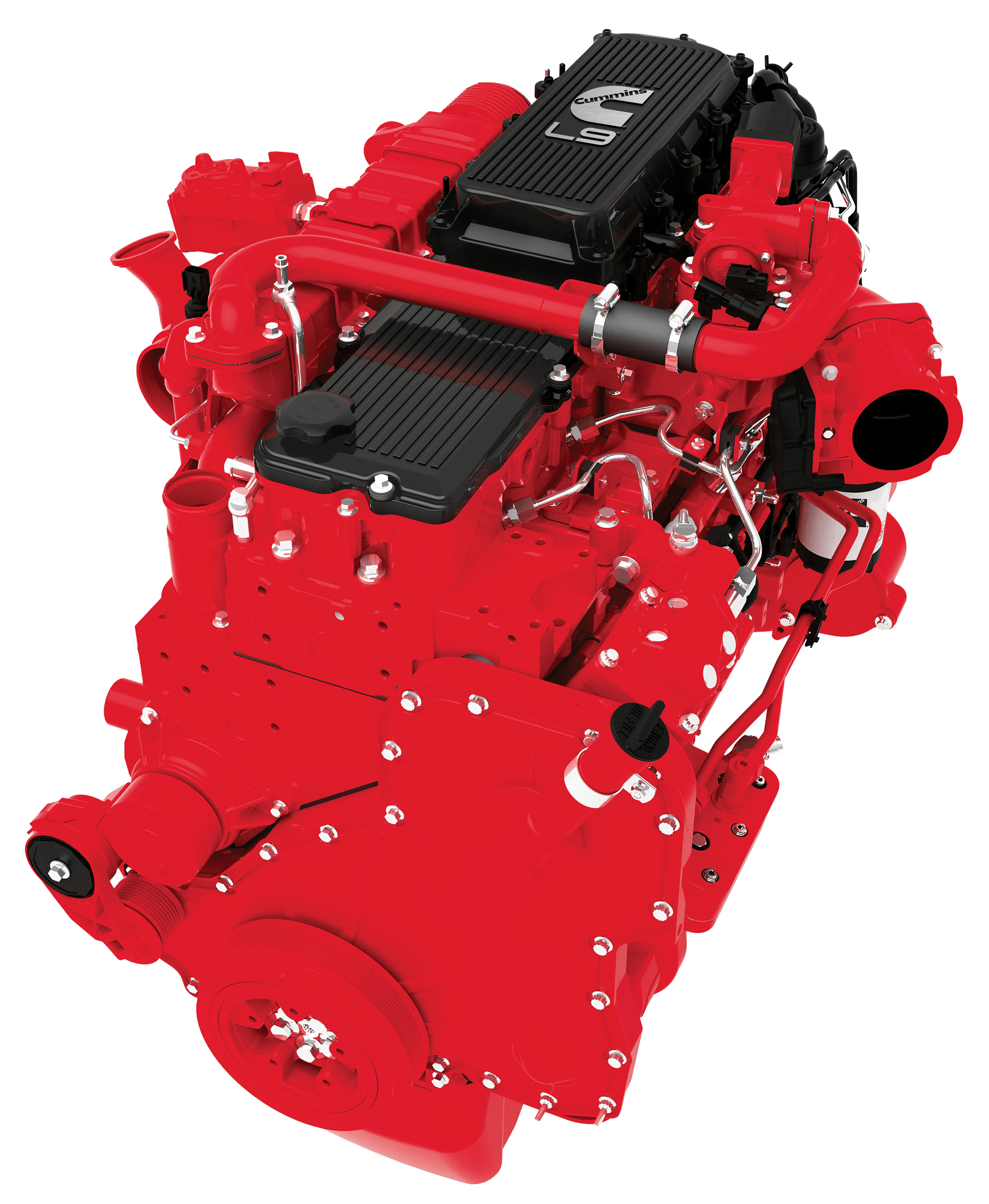

L9 for Shuttle Bus (2017)

Power

260 - 380 hp

Torque

720 - 1250 lb-ft

Certification

EPA 2017

X15 For Motorhomes (2017)

Power

565 - 605 hp

Torque

1850 - 1950 lb-ft

Certification

EPA 2017

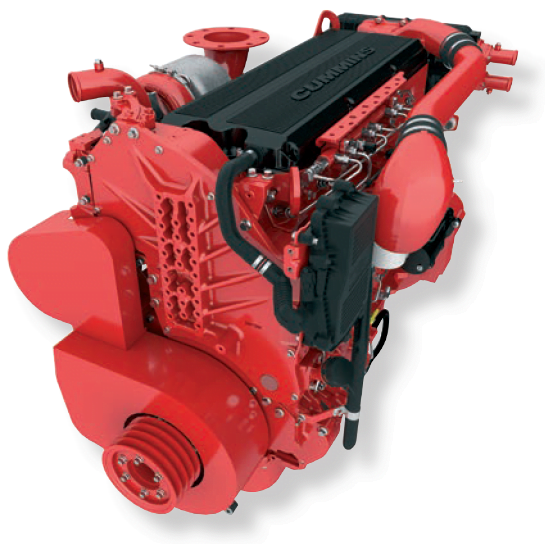

X15 (Stage V)

Power

450 - 675 hp

Torque

1600 - 2050 lb-ft

Certification

EU Stage V